Antarctica’s Concordia Station recently experienced a new record temperature: -84.6° C, or -120.3° F. Not many things operate well under such conditions, but one telescope mount — which has to move continuously — happens to be one of them.

At the Laboratoire Universitaire d’Astrophysique de Nice (LUAN) in Antarctica, temperatures can drop to over 100° F below zero. The telescope is connected to an Astro-Physics 3600GTO mount for continuous tracking of astral bodies.

Astro-Physics, which designs and manufactures telescope mounts, has proven their resilience through the installation of several of their 900GTO and 1200GTO mounts at Concordia’s Dome C location. These mounts have been operating continuously at Dome C since the early 2000s. Long life is critical for these systems because maintenance is so difficult there. Low temperatures and dangerous wind conditions prevent technicians from working outdoors, and the mount must be reliable 24 hours per day for the entire six month polar night.

Their latest mount installed at the site, the 3600GTO, is the largest mount used at Dome C to date. One of the most important aspects of every telescope in the world is the gear reduction system used in the mounting apparatus. In order for a telescope to maintain a consistent bead on a particular star or system, it must move continuously. If a telescope is not driven, the image of a star will drift out of the field of view very quickly. The higher the telescope magnification, the more the Earth’s rotation is magnified—so the target will appear to move.

In order for a target to stay “fixed” in the viewing field of a telescope, the mount has to move continuously. Astro-Physics’ precision mounting systems are for use with telescopes ranging from 50 lb to ones like the Antarctica telescope that weighs a quarter ton.

“Every system we build uses maxon motors,” explains Wally Piorkowski, Head of Mount Production/Scientist for AstroPhysics.

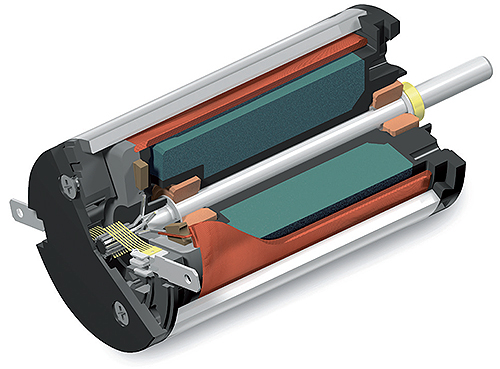

The grease used in the motor’s bearings is ideal for harsh/extreme temperatures, such as the severe conditions experienced in Antarctica. Once in place, the maxon motors do not need to be greased, a key requirement in such severe conditions as those at Dome C. maxon motors also feature an ironless core designed with neodymium magnets, which provide the highest power available relative to motor volume. For mechanical commutation, the motors are provided with either graphite or precious metal brushes. And for the applications on mounts, the motors offered linear characteristics making them easy to implement. Of course, reliability is one of the more important characteristics that make maxon motors ideal for such an application.

There are two axes designed into each mount. One axis, the right ascension axis, is mounted parallel to the Earth’s axis and follows the Earth’s movement. The motor is driven in the opposite direction of the Earth’s rotation, so that the target object looks as though it is fixed in the sky. The reduction drive is designed by Astro-Physics.

The declination axis is mounted at a right angle from the ascension axis. With the two axes mounted at right angles from one another, the operator can aim the telescope anywhere they want. The encoder is used so that the motor can adjust and correct its position on an intermittent basis.

“We use A-max motors for our smaller mounts and RE25 motors for mounts like the one at Dome C,” Piorkowski said. “A major factor in using maxon motors, though, is that they have no cogging.”

Astro-Physics uses maxon motors in all their mounts because of the products’ high reliability and long life. maxon motors are available in both dc brushed or brushless and are ideal for harsh environmental use.

Cogging, or detent, is the jerky motion most iron core motors exhibit while operating slowly. maxon motors use an ironless core design that eliminates cogging, even at slow speeds like those needed for telescope mounting systems.

“Often our mounts are bought separately from the telescope itself,” Wally said. “Astronomy clubs, schools, associations, etc. buy the telescopic equipment and the mounting system separately then put them together themselves.”

The company’s 3600GTO and 3600GTOPE mounts have also been installed in a variety of domestic locations including universities, research organizations, astronomy clubs, community organizations, and foundations committed to the education of children. Companies engaged in solar power research have also used the company’s precision mounting systems.

Discuss this on The Engineering Exchange:

maxon precision motors, Inc.

www.maxonmotorusa.com

Filed Under: Gears • gearheads • speed reducers, Motion control • motor controls, Motors • dc

Tell Us What You Think!