The Ti 6/4 ELI (Grade 23) titanium strip comes in thickness gauges as low as 0.004 in. The result of a newly developed proprietary technology, these ultra-thin Ti 6/4 ELI (extra low interstitials) titanium strips demonstrate improved ductility and formability, making them ideal for such applications as pacemaker and neurostimulator enclosures. This titanium alloy is becoming the preferred material for orthopedic devices and medical implants because of its high strength, fracture resistance and compatibility with the human body.

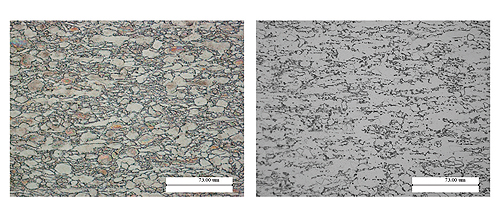

The proprietary technology uses a cold rolling and annealing process that yields titanium strip with outstanding microstructure characteristics and improved tensile strength and formability properties. Cold rolling eliminates the need to grind away as much as 50% of the starting material to achieve the thinness. It also leaves zero opportunity for embedding grinding material on the surface of the finished strip. The annealing process significantly lowers hydrogen content and removes residual stresses. Ti 6/4 ELI titanium alloy strip is available in sheets up to 6 in. wide with thicknesses ranging from 0.004 to 0.015 in.

AMETEK Specialty Metal Products

www.ametekmetals.com

Filed Under: Medical-device manufacture, Materials • advanced

Tell Us What You Think!