Zero-Max, Inc. announces expansion of its wind turbine couplings covering a broad range of wind turbine applications. Zero-Max Wind Turbine Couplings are now available as an upgrade replacement for existing wind turbines and for OEM applications.

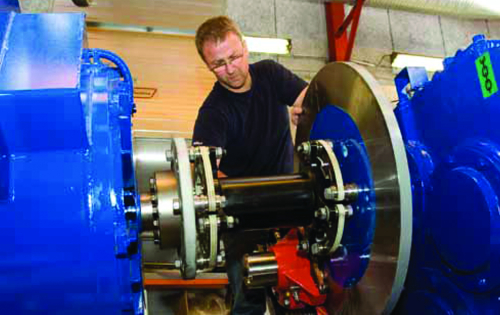

Proven and tested under conditions simulating a 20-year load spectrum of continuous operation, Zero-Max turbine couplings easily handle torque spikes and high misalignment installations.

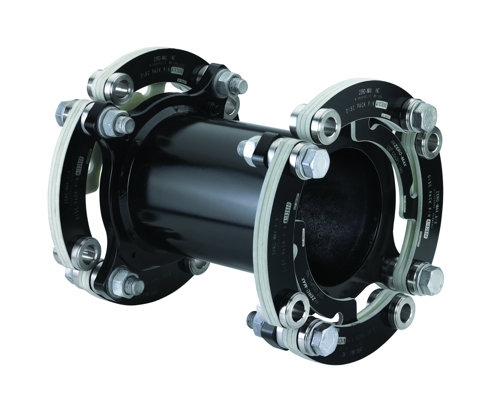

Zero-Max couplings withstand high misalignment while remaining torsionally stiff. They are designed with composite disk packs at both ends of a center spacer. These uniquely designed disk packs provide high strength and generous flexibility. The composite disk packs (flex elements) provide a distinct advantage over other coupling component designs by allowing a surplus of parallel and axial misalignment while remaining torsionally stiff through all harmonic ranges of the wind turbine’s oscillating load.

Depending on the application, Zero-Max’s center spacers can be machined out of steel, composite glass fiber, or 6061-T6 aluminum. Through the use of Finite Element Analysis (FEA), these center spacers can be engineered to withstand in excess of 100,000 Nm of torque.

Zero-Max wind turbine couplings have many additional design advantages. The flex elements electrically insulate the turbine’s generator from the gear box, eliminating stray electrical current that can leak across the coupling, thus preventing bearing damage to the gear box. The coupling protects the generator by transferring lower reaction loads to the generator bearings. Also, the coupling’s composite material withstands all types of environmental elements, including temperature extremes from -40 to +70°C, and also moisture and chemicals native to the nacelles of wind turbines.

Zero-Max

www.zero-max.com

::Design World::

Filed Under: Couplings, Green engineering • renewable energy • sustainability, MECHANICAL POWER TRANSMISSION, Motion control • motor controls

Tell Us What You Think!