Correlated Magnetics Research (CMR) has been awarded a Small Business Innovation Research (SBIR) grant from the Office of Naval Research (ONR) to design and develop high-torque magnetic gears and couplings using CMR’s PolymagnetTM technology. The two-year contract is valued at $747,995 and is a collaborative effort between the U.S. Navy, CMR and MagnaDrive, Inc., of Woodinville, WA.

CMR will design and develop Polymagnet-enabled magnetic couplings to produce quiet, maintenance free, power-transfer linkages for Naval systems, DoD, and industrial applications. The effort is a follow-on to ONR’s Phase I research project performed by CMR and directly addresses the Navy’s requirements for noise and maintenance reduction for on-board pumps, electric-drive machines and propulsion systems for naval vessels.

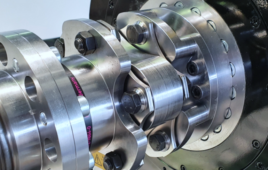

Traditional mechanical couplings and gears require lubrication, generate heat, emit vibrations and sound, suffer from structural wear and require significant maintenance. Interlocking magnetic fields on the other hand, require no physical contact and thus no lubrication. They also suppress vibration, eliminate structural wear and virtually eliminate maintenance requirements. CMR’s proprietary multi-pole magnetic structures overcome the shortcomings of current magnetic couplings: low torque transfer performance, strong tensile (non-torque producing) forces between the magnets and large, heavy rotating mass.

Referring to the potential for maintenance-free operation, ONR’s Dr. Scott Coombe said, “This alone is reason to pursue development of magnetic gearing for propulsion, power generation and actuation.”

The Phase II project includes magnetization research, creation of industrial-scale complex magnetization capability, prototype development and full-scale magnetic coupling development. CMR and MagnaDrive will commercialize the coupling technologies following completion of the effort.

Correlated Magnetics Research, LLC

www.correlatedmagnetics.com

Filed Under: Couplings