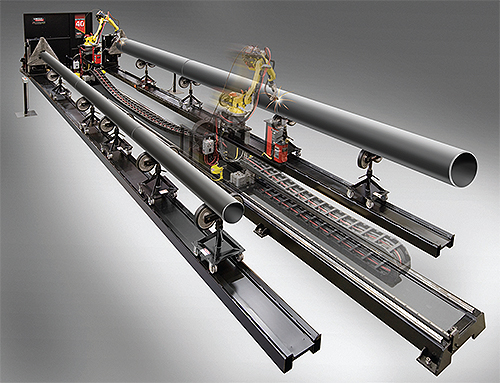

About 20% of industrial robotic applications involve arc welding. As with most technologies, that number could be higher if some technical or application restrictions were removed. A new robotic arc welding system claims to expand the available solutions for submerged arc welding (SAW) with a robot.

At the core of this next generation system is a wire and flux delivery system. Integrated with the torch design, this streamlined flux delivery lets you incorporate robotic SAW systems on corners and path variations.

The system uses the Power Wave® AC/DC 1000® SD welding power source. The machine output is rated 1000 A, 44 V at 100% duty cycle. With 380-575 Vac, 50/60 Hz input voltage capability, the Power Wave can be connected anywhere in the world.

The digital inverter-based power source features the software-driven Waveform Control Technology® for control of dc positive, dc negative, balanced ac and variable ac submerged arc processes without cumbersome mechanical cable swapping. Subtle waveform changes can be made for precise control of the submerged arc deposition rate and penetration. The result over conventional power sources is increased weld speeds, consistently higher quality welds, and improved efficiencies in single or multi-arc environment.

The Power Wave machine features new iArc™ digital controls, delivering processing speeds up to 90 times faster than the previous generation. The result is faster arc response and greater arc stability.

Another feature enables remote weld process monitoring for efficiency analysis. With Production Monitoring™ 2 web-based software, you can track equipment usage; gather and store data by weld, station, shift, or date; configure welding process limits; and generate e-mail alerts. The system’s True Energy™ feature lets you measure and display energy for critial heat input applications.

Additional capabilities can be added to the robotic system, such as Touch Sensing, automated path follow and vision-based systems for tracking, guidance and error proofing.

The Lincoln Electric Co.

www.lincolnelectric.com

::Design World::

Filed Under: Machine tools + subtractive manufacturing, LINEAR MOTION, Motion control • motor controls, Mechatronics

Tell Us What You Think!