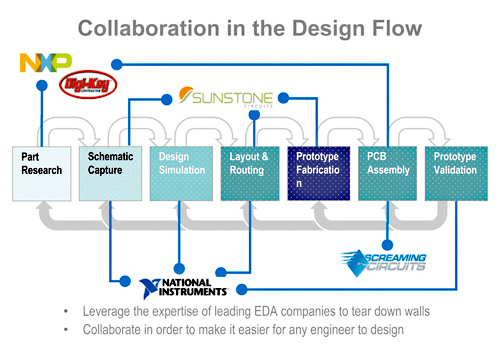

Traditional printed circuit board (PCB) design involves many individual operations including part research, schematic capture, design simulation, layout and routing, prototype fabrication, PCB assembly, and prototype validation. This “over the wall” approach can cause significant delays because each step in the process is typically performed in a vacuum.

What’s more, in today’s changing engineering environment, design teams are smaller and are being asked to do more at a faster rate. To help resolve these issues, ECOSystems was formed — a collaboration of electronics industry experts focused on providing a process that will help shorten time to market, increase efficiencies, and deliver a better quality product at reduced project costs.

Industry leaders collaborate within the Circuit Design ECOsystem to help provide solutions for electronic design engineers.

Cyth Systems is a National Instrument (NI) Alliance Member using NI tools to deploy complete solutions to its customers. The company was looking for ways to create clean, efficient, and robust interfaces to external systems based on NI Single-Board RIO platform. They used the NI Multisim and NI Ultiboard prototyping tools to create a daughter card to break out signals to various screw connectors. The NI prototyping tools were used to design the Circaflex daughter card because of the technology ease of use and flexibility.

Through ECOsystem and particularly NI and Sunstone Circuits, Cyth was able to quickly move their designs into the final prototyping stage. It was important for Cyth to turn their Circaflex schematics and board layouts into a prototype to evaluate how it will interface to the Single-Board RIO platform. By working with Sunstone Circuits, Cyth was able to leverage the quick prototype turnaround to evaluate their design decisions and test their complete system. The final result is a more effective design approach with a faster transition from design tools to hardware prototypes.

Cyth Systems

www.cythsystems.com

National Instruments

www.ni.com

Sunstone Circuits

www.sunstone.com

::Design World::

Filed Under: Computer boards, ELECTRONICS • ELECTRICAL

Tell Us What You Think!