From induction motors in electric vehicles to tiny coreless dc motors in drug-delivery equipment, electric motors continue to proliferate. Last year we saw consumer products, implantable medical devices, and automation of previously manual tasks spur the most innovation in motor design and use. This year those trends continue — and now we see increased use of servo and stepper motors in robotics.

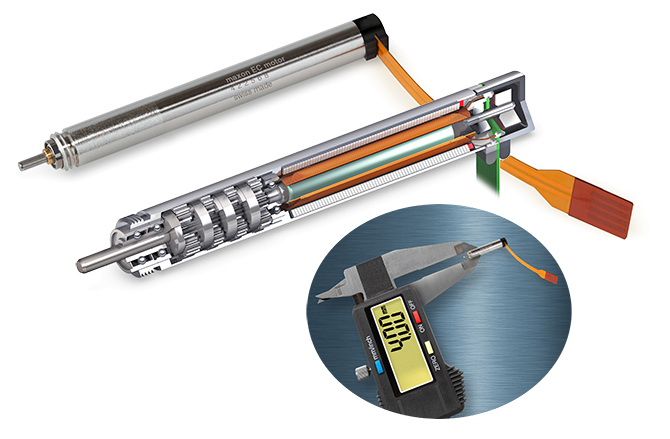

maxon precision motors EC 4 brushless dc motors (which can be fitted with GP 4 planetary gearheads) are 4 mm in diameter with an ironless winding; ISO 13485 certified; and suitable for use in laboratory robots, micropumps, and diagnostic devices. Two lengths deliver power to 0.5 and 1 W. “We also want to offer more value-add services, as more companies than ever in the U.S. want finished motor and motion systems — so-called drop-in designs,” said McGrath of maxon. “So to that end, our expanding U.S. factory will have the capacity to supply custom assemblies and PCBs.”

In fact, whether it’s basic tin-can motors for low-cost custom actuation or integrated motors that output servo-like performance, overall use of stepper motors is growing. On the latter, a study by P&S Market Research projects a CAGR of 6.3% through 2023 for the global closed-loop stepper motor market. P&S cites the well-known benefits of control-feedback signals and power-adjusted current control as key reasons for the technology’s steady adoption.

Low-current dc motors from ISL Products Intl. Ltd. come in myriad mechanical and electrical configurations. Sometimes gearmotor modifications help the dc motors meet exacting OEM application specifications. In other cases, the motor must have special construction to avoid inducing EMI and RFI interference (Here, raw materials in the motor components are a main consideration, said to Kawaller of ISL.) Designs with reduced power consumption benefit from motors with specialized internal construction and nontraditional component materials.

Warren Osak, CEO of Toronto-based distributor Electromate Inc., sees this trend for integrated stepper motors, even while the middle of the stepper-motor market (actuated by standalone 1.8° hybrid stepper motors) recedes. Technology is either migrating upward (and taking the form of integrated motors or smart motors) or migrating downward — to lower-cost motors with less sophisticated structures, according to Osak.

“The use of traditional hybrid stepper motors has been yielding to integrated products … while in lower-end applications, we see more use of less-sophisticated motors with customer-provided integrated chips (ICs) to drive them,” he added.

Full interview with Osak: Motion-control trends distributor insight

Some closed-loop stepper manufacturers we surveyed for the Design World Trends issue include Schneider Electric Motion USA, Applied Motion Products Inc., Lin Engineering, MICROMO of Faulhaber, Oriental Motor Co., and Nippon Pulse America Inc. — with commentary from the latter in our actuator trends coverage. All detail pre-integrated or application-specific motor offerings. Case in point: Automation in the oil and gas industry has created numerous opportunities for motion control products, but stringent requirements for hazardous location ratings rule out most standard motor and drive solutions.

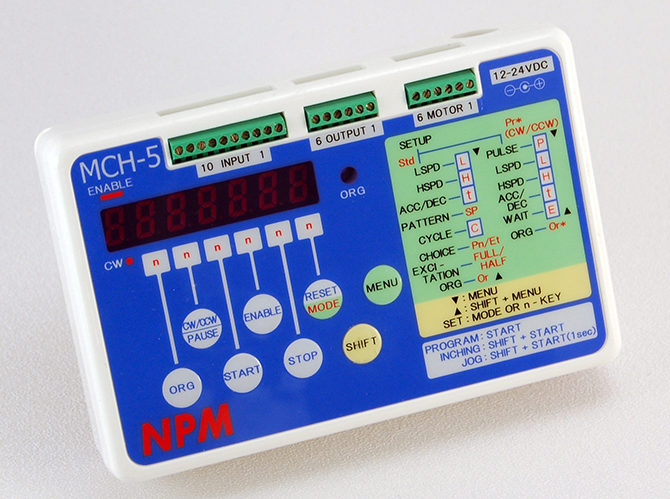

Use of tin-can stepper motors is on the rise, and now some new tools let engineers check their programming on the little motors more easily. Consider the Motion Checker 5 controller from Nippon Pulse America Inc. — a standalone handheld controller with an integrated driver circuit. Using it is as simple as plugging it into a normal outlet and connecting a stepper motor to run through motion sequences.

“To serve engineers in this industry, we’ve released the world’s only ATEX-rated stepper drive for hazardous locations … and this year we’ll introduce our first explosion-proof step motor to pair with it,” said Eric Rice of Applied Motion Products. “The drive is already being used on rigs in the oil field for applications where accurate braking and speed control of drill strings are required.”

Motors in (proliferating) battery-powered designs

Battery-powered designs such as ATVs, mobile robotics (including AGVs), scooters, ebikes, and drones present unique motion-system challenges. Motors that integrate into these designs might need to accept 48, 24, or 12-V input, and nearly all of them must meet tough efficiency requirements … NEXT PAGE →

Filed Under: Drives (stepper) + amplifiers, Gears • gearheads • speed reducers, Motors (direct-drive) + frameless motors, Motors • stepper, Motion Control Tips

Tell Us What You Think!