20 years ago, Michael Prokopp co-developed a type of new electric motor to outperform traditional motors. This synchronous torque motor reaches very high torque at low speeds and is more efficient than many traditional motors.

While leading manufacturers in this industry get 76% efficiency form comparable motors, the EMF motor is 94% efficient — a quantum leap in motor efficiency, according to managing director of EMF97 Gmbh Michael Prokopp. This is in addition to a motor price that’s half that of comparable motors.

While leading manufacturers in this industry get 76% efficiency form comparable motors, the EMF motor is 94% efficient — a quantum leap in motor efficiency, according to managing director of EMF97 Gmbh Michael Prokopp. This is in addition to a motor price that’s half that of comparable motors.

Prokopp and his colleagues aim to replace conventional electric motors and mechanical gearboxes. “Traditional systems are noisy; consumes oil; are subject to wear; and must be constantly maintained,” said Prokopp. He patented the EMF motor principle and in 1997 (with co-inventor Jurgen Lindner and two partners) founded EMF97 GmbH. Initially, industry responded cautiously … and viewed the motor technology with skepticism. The turning point was at the 2002 Hannover Fair. Turkish businessman Hasan Kayakiran and the founders of EMF found interest in Turkey … so in cooperation with Kayakiran, a production facility was established in Istanbul (even with development still in Worms, Germany).

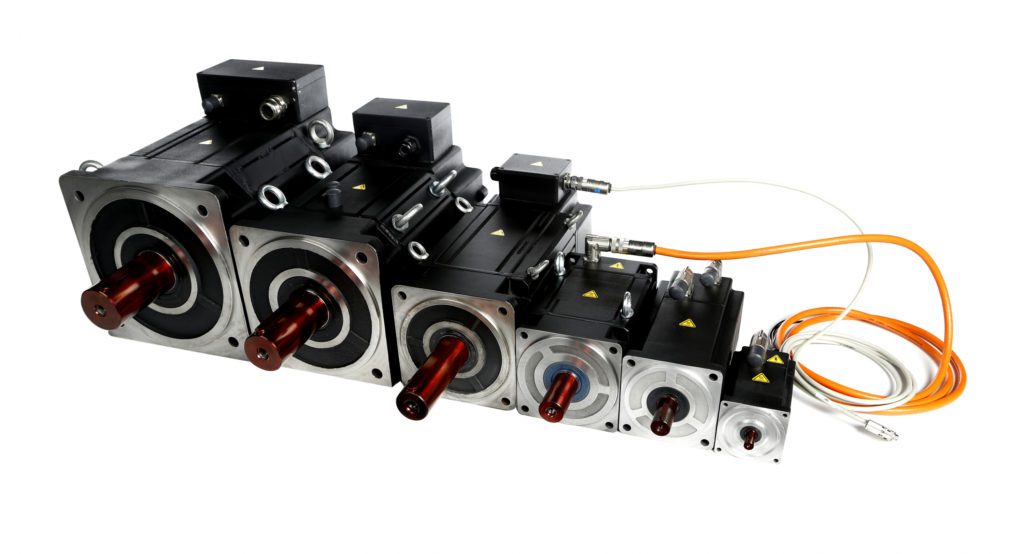

Now 15 years and some 10,000 motors later, EMF motors are used in many applications. Currently their most common in elevators and extrusion machines. In March, EMF was honored in Istanbul with a German-Turkish Innovation Award. No wonder, as growth is on the horizon: In November 2016, EMF97 filed a new patent for a motor targeted towards the wind-power industry … and EMF97 sales near doubled last year.

Basics of how EMF motors work

The wound stator of the EMF motor is almost the same as a traditional motor. Magnets are glued to the rotor. Input voltage and a frequency spur a magnetic flux to magnetize the motor. As frequency increases, the electric field in the wound stator begins to turn. The rotor moves in a direction opposite the rotating field — and more slowly. The number of magnets and the geometry of the motor defines the speed ratio. The motor outputs very high torque with a low number of winding poles; low copper and hysteresis losses keep efficiency high.

The high number of magnetic poles impart smooth ripple-free rotation and dynamic performance. Plus these motors need no additional cooling, so there’s no other motor design with comparable efficiency or such a high torque-to-weight ratio.

Filed Under: Motors (direct-drive) + frameless motors, Motion Control Tips

Tell Us What You Think!