Up until the 2008 collegiate basketball championships, portable basketball backstops common to large sporting arenas were manually operated. Spalding, one of the world’s oldest and best-known sporting good brands, saw the opportunity. Under the pressure of the fast approaching Final Four, they stepped up to develop a motorized backstop that could do the job automatically—in less than a minute.

Spalding’s design engineers did a lot of groundwork and brought “10 feet of spreadsheets” to the design table. In collaboration with the Groschopp engineering team, they set out to develop a motor for this 25 second raising and lowering requirement.

The primary design challenge was the torque requirement. The automated backstop operation called for a gearmotor to lift over 600 pounds. Because the weight was positioned at the end of an articulated arm, it magnified the impact of the weight and presented a calculated total torque requirement of over 700 in-lbs.

“Putting enough torque into the gearbox was one of the tougher challenges. We had to operate the motor on a standard 110 VAC, 20 amp circuit, which limited options,” said Loren Kamstra, the Groschopp applications engineer on the project. “We also had to calculate the exact torque requirement at each of the lift points, making it an even more complex engineering problem.”

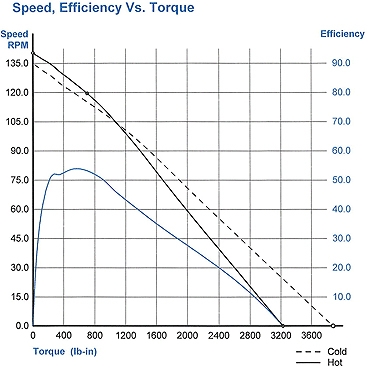

The scissors-like action of the lift mechanism, coupled with a load on the end of the articulated arm, meant that the torque varied at different points throughout the operation cycle. “In our test setup at a local college, we monitored amperage throughout the cycle,” added Kamstra. “Then we used the amperage data and MOTORTEC™ to calculate the torque based on the motor’s current draw.”

The gearmotor chosen after extensive calculations and testing was a permanent magnet DC (PMDC) motor with a speed of 4250 RPM, and a high-torque right angle gearbox with a 30:1 output ratio. Using 115 VAC with a transformer boost to 230 VAC and a rectifier produced 180 volts DC–and enough torque to lift the hoop and shot-clock smoothly and quietly within the 25 second limit. Testing included a five year life test (2000 cycles) and current draw tests, to rule out circuit overload.

Meeting the Final Four deadline, Spalding is now selling their portable backstop with the Auto Lift Mechanism (ALM) to both college and professional teams, allowing for one step set-up without tools.

The Challenge

• High torque to lift a heavy glass basketball backboard and shot clock positioned on the end of a pivoting boom – weighing 600 pounds

• 25 seconds to raise and lower the backboard to ten feet (to regulation hoop height)

• Total calculated torque requirement of 702 in-lbs

• Power supply of 110 VAC on a 20 amp circuit

The Solution

• DC motor operating at 180 VDC matched with a high-torque right angle reducer (30:1), coupled to a massive 1½” diameter lead screw

• Lifts 600 lb. backstop in 25 seconds

• Transformer and rectifier converting 110 VAC to 180 VDC for added power

• Life tested to 2000 cycles, or 5 years

TOUGH JOB

Design Checklist

Torque Requirements

It’s important to take position into consideration when calculating torque requirements. In an application such as this one, with the variable (moving) position of the load, the torque will also vary—it’s NOT linear.In testing, be sure to take current draw measurements on the motor, then use that data to calculate torque. Determining the maximum torque point (from the highest current reading) allows you to ensure that the gearmotor is properly sized for reliable operation throughout the entire range of motion.

For complete gearmotor specifications, visit http://www.groschopp.com

::Design World::

Filed Under: Motion control • motor controls, Motors (gearmotors)

Tell Us What You Think!