The ESA’s Solar Orbiter is primed for a 2020 launch, ready to measure the sun’s solar wind from a minimum distance of 42 million km (about 26 million mi). To put that into perspective, that’s less than one-third Earth’s distance.

Being that close to the sun spells a hot mission for the Solar Orbiter. It’ll experience 13 times more solar heat than Earth’s orbiting satellites, and trudge through temperatures soaring to more than 500°C (932°F).

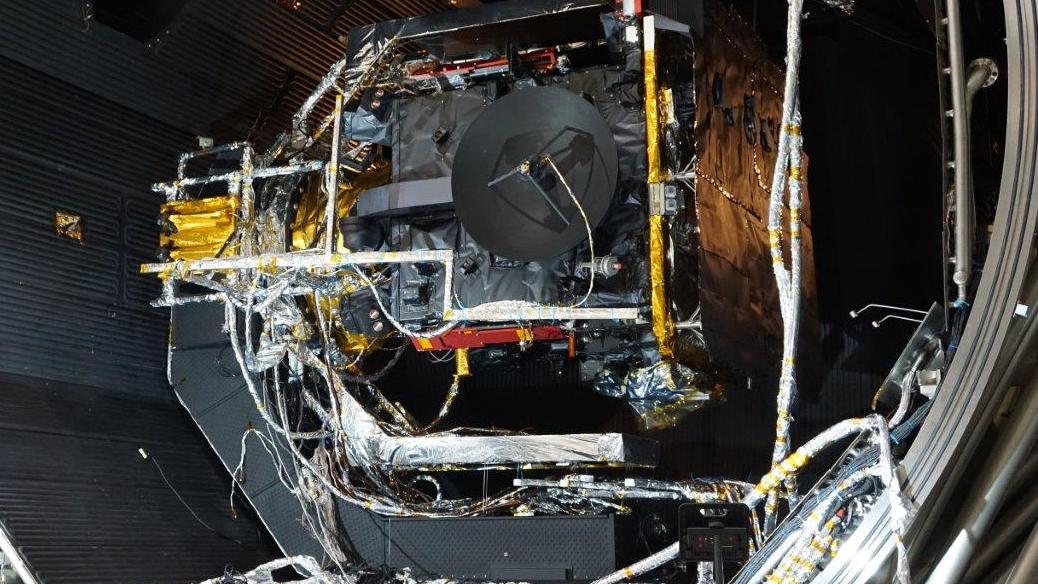

To make sure the spacecraft can function under these harsh conditions, it’s going through a series of trials, which is why it traveled last month to the IABG test facility in Ottobrunn, Germany (Figure 1). There, the orbiter entered a vacuum chamber for thermal vacuum testing.

(Image Source: Airbus Defence and Space)

The current campaign also used powerful lamps to simulate the sun’s radiation, akin to what the spacecraft will experience as it travels to its operational orbit through flybys of Earth and Venus.

The final design will have a main body with a multi-layer titanium heat shield to protect it from the Sun’s direct light.

“During 99 percent of the mission operations time, the heatshield will protect Solar Orbiter, but there will be more than a dozen maneuvers when one of the side panels will be exposed to sunlight,” says Claudio Damasio, ESA’s Solar Orbiter project thermal engineer. “Therefore, we need to know how the Proto Flight Model responds when the exterior of the insulation on these panels reaches a temperature of about 120–150°C.”

The photo also shows the high-gain antenna, which sports a black color. According to the ESA, “It is covered with the same kind of protective, high temperature coating as the front of Solar Orbiter’s heatshield, based on burnt-bone charcoal. Developed by Irish company ENBIO, this ‘Solar Black’ coating was selected because it can maintain the same color and surface properties despite years of exposure to unfiltered sunlight and ultraviolet radiation.”

The antenna will sit at the end of a boom that’s 1 m long, providing a dependable, high-bandwidth connection with Earth.

Filed Under: Aerospace + defense