A fully automatic final assembly line for electric motors in the automotive sector. Optionally, fast and precise automated size changeover SIKO positioning drives can be used with such a system from Braun Sondermaschinen GmbH.

| Braun Sondermaschinen GmbH

Automation, Industry 4.0, and Big Data are the key technology trends in the industrial sector. Braun Sondermaschinen GmbH recognized these trends early and used them for developing fully automated production lines, increased customer productivity, and savings. Building specialized machinery requires individual concepts and flexible solutions. Therefore, the company has developed the modular automation concept MAK, which includes both software and hardware. Smart components are also used to make the processes within the systems even more efficient and safer. These components also include AG24 positioning drives from SIKO GmbH, a manufacturer of sensors and positioning systems. They enable an automated size changeover for more precise adjustments when changing products and faster refitting times.

Manuel S. Gander, M. Sc., Head of Supply Chain Management and Material Management at Braun Sondermaschinen GmbH, explains the requirements for building specialized machinery, “The automated production lines that we implement are developed according to specific and individual customer requirements — usually as a prototype and then as an adapted replica of the prototype. No two systems are alike; there are always special requirements.” To ensure a certain level of standardization remains, the company offers a modular automation concept, “The MAK system consists of an aluminum traverse and a protective housing. Depending on customer requirements, the individual processes are modularly linked in, and a software package is fitted over the entire system.”

Another aspect that is taken into account in system planning is the increased number of variants that machines must handle even with the smallest batch sizes. Compact positioning drives enable automated and fast size changeovers without significant intervention in PLC programs. Braun Sondermaschinen GmbH always uses the AG24 positioning drives from SIKO when manual workstations requiring automation need precise size changes. These are balancing systems (assembly and balancing machines) to produce cooling fans for the automotive supplier industry. Until now, balancing has been a manual process in which the special machine manufacturer had already used SIKO’s mechanical position indicators for manual size changeover. With the AG24 positioning drive this module can quickly and precisely be converted to manage the increasing number of model variants.

The AG24 actuator was selected partially for its high torque and the associated power reserves. This power range is not always necessary for systems, but the reserve option plays a major role. For example, if components become more difficult to move due to dirt and stress and the drive can then provide more power.

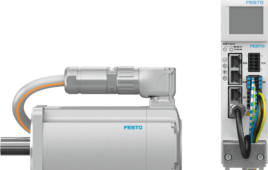

Servomotors are an alternative to positioning drives, and are justified in most processes, but less so when compactness and manual operations are important. With the AG24, all necessary functions, such as the brushless DC motor, position encoder, or power and control electronics, are already integrated into the device. It can be connected directly to the machine control, is compact, and unlike a servo motor, which requires additional components such as variable frequency drives or inverters, it does not require any wiring. The positioning drive also has an integrated absolute encoder that records the position at all times, even when the power is off.

For Jürgen Schuh, Business Unit Manager of Changeover Solutions at SIKO, this also demonstrates the advantages for a special machine manufacturer like Braun, “Every project is accompanied by a new set of specifications, with additional possible variants, which in turn involve special requirements.

With a maximum rated torque of 14 Nm, the new positioning drive AG24 packs a punch for size changeover.

| SIKO GmbH

The AG24 also provides the possibility of controlling the drive via the fieldbus and the PLC and using the option for changing manual settings directly on the device display. In some applications, it makes the most sense to change the settings and positioning manually in advance via teach-in; in other words, to gradually travel to the appropriate dimension with the positioning drive and then save these positions as target values in the machine control system. In this way, the finely adjusted positions can be traveled to directly during commissioning. The AG24 positioning drive combines both aspects – the manual fine adjustment and the automated, efficient process.

“From an electrical design standpoint, the integration of the actuator is also very straightforward, including integration into the machine control system,” said Gander.

Gander also said another aspect that will become more essential for his customers is the collection and evaluation of data on the production lines. Besides determining the position, the drive can also show additional diagnostic data, such as current consumption or temperature, both on the display and via the interface. Conclusions can be drawn from this data regarding predictive maintenance, allowing maintenance intervals to be planned. The drive thus also supports requirements related to Industry 4.0 and data evaluation via AI.

Gander sees great potential in this diagnostic capability because his idea of the ideal automation line is “a system in a dark hall, in which production can run 24 hours, seven days a week, 365 days a year without human intervention”. This vision is not far away; human judgment is still mandatory for certain processes, but the greater the number of unnecessary, tedious, or error-prone process steps that can be automated, the more efficiently production can be carried out. For the special machine manufacturer, one thing is clear: “Not only is full automation increasing steadily, it is becoming the standard in industrial production.” Intelligent peripheral components such as positioning drives play an increasingly important role. DW

SIKO

siko-global.com

Filed Under: Drives (ac) + VFDs + starters