By Roger Hess, Sales and Applications Engineer, Maxon Precision Motors, Inc., Fall River, Mass.

A Florida company designed a robotic crawler to navigate around the underwater portion of a ship and remove accumulated biofilm layers. As a battery operated, autonomous vehicle, component selection made up a highly critical part of the design and manufacturing process

Toxic paint is used on the bottom of large ships to prevent biofilm growth, a form of fouling that increases the ship’s drag and decreases efficiency. Although it is quite effective, the downside is that the toxic paint continually leeches copper and other heavy metals into the underwater environment and damages the organisms that live there. To make the matter more complex, the paint must be blasted off and replaced every 5 to 10 years, at which time tons of toxic waste is produced and must be properly disposed.

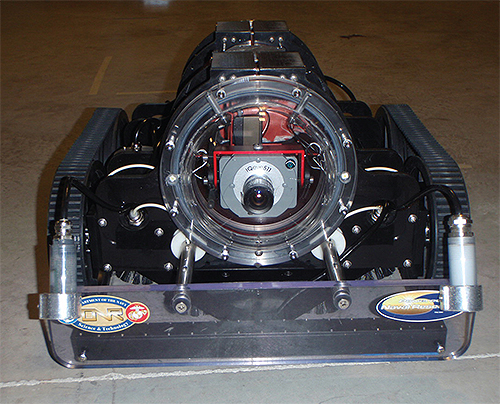

The HullBUG grooms the biofilm that collects on the underwater portion of ships.

A ship that operates with a clean underwater surface free from fouling—even thin biofilm layers—will operate so much more efficiently that potential savings can easily reach over 5% in fuel costs alone. Without the concern for fouling, a ship’s underwater coating can be engineered for corrosion protection and longevity rather than its need to eliminate the potential for biofouling. If biofilm fouling was eliminated on all the ships operating in the world today, the energy savings would greatly reduce the presence of greenhouse gases.

To eliminate the requirement for toxic paint and its cleaning waste, there needed to be a method to “groom” the biofilm from the underwater portion of a ship. The idea was to create important changes for the ships being built as well as for the environment. That is where the HullBUG (Hull Bioinspired Underwater Grooming) concept originated.

Successful promotion of the HullBUG concept by SeaRobotics, Palm Beach Gardens, Fla., attracted the attention of the U.S. Navy and specifically The Office of Naval Research (ONR). A successful proposal was submitted to the ONR for funding and a project team was established. The team currently uses SeaRobotics as a system designer and integrator and the Naval Surface Warfare Center Carderock Division (NSWCCD) as the team manager. The Florida Institute of Technology is also employed to provide a strong knowledge and research base for understanding how the biofilms affect ship efficiencies and what is necessary to combat them.

“The most important feature of the HullBUG is its small size,” says SeaRobotics’ Research Engineer, Dr. Kenneth Holappa. “It is only about half a meter in length.” This was a necessary design feature to allow the vehicle to maneuver over the curved surface of the hull while continually maintaining close contact with the surface. An additional benefit of the size was that it allowed a single operator to deploy the vehicle without the use of additional equipment such as a crane. Because of the hazards associated with operating such a device underwater and in a harbor environment, occasionally a HullBUG might be lost or destroyed during operation. Keeping the size and cost of the system low definitely helped to eliminate damage as a major obstacle to implementation. So, from the very beginning of the project, small size and low cost have been identified as being critical to the satisfactory implementation of the HullBUG project. As can be expected, this need to maintain a particular size and weight filtered into the selection of every component of the design.

Motion Control Components

The selection of the motors to drive the HullBUG involved a number of critical engineering constraints and compromises. SeaRobotics decided to make two basic models, one with wheels and one with tracks, and offer several options for monitoring the system’s progress.

This close-up of the HullBUG clearly shows its sensor alignment system that helps it keep on course while cleaning a hull.

Motor sizing, for example, required a calculated estimate of the power, speed, and torque characteristics of the manufactured devices. Determining factors included the resistance caused from pushing the grooming tool across the surface of the ship, the hydrodynamic resistance of the vehicle itself as it moved through the water, friction losses in the shaft seals that were used to protect the motors from the saltwater, and track or wheel friction dependent on which version of the unit was used.

“After extensive component research, we chose to use Maxon motors and gearheads,” says Holappa. “Their motors not only provided a very cost effective solution, but they were highly efficient and extremely simple to implement.” The company used EC flat motors with planetary gearheads. Two motors were used on the tracked version of the HullBUG (one for each track); while four flat motors were needed for the wheeled version (one for each wheel). An additional EC flat motor was implemented in the grooming tool. That motor used a simple spur gear for speed reduction. In addition, a final motor, connected directly, was used for the negative pressure attachment device that held the HullBUG in place.

The EC45 4-pole flat motors selected for the HullBUG are very efficient and weigh only 2.2 pounds. Continuous output power is 200 W, while the maximum speed is 12,000 rpm (much faster than what was needed for this application). The important specification for this application was torque. Even under the potentially harsh environments in which the HullBUG would be engaged, the EC45 had a maximum continuous torque up to 37 oz-in. (265 mNm), depending on the winding chosen. The Maxon brushless motors are built to IP54 standards, which was critical to the application. Furthermore, the motors are also available in the system voltage that SeaRobotics requires for the HullBUG application. According to Holappa, the large load capacity of the shafts of the GP42 gearhead let the wheels mount directly to the gearhead shaft, which greatly reduced the complexity of the overall system design.

Because the HullBUG vehicle was to be completely autonomous, it had to be designed in such a way as to operate for many hours on batteries (cables would simply get in the way of the grooming operation). In order to maximize battery life, the biofilm grooming had to be done in the most efficient manner. Navigating in a random pattern may eventually get the job done, but not in a reasonable amount of time. In addition, a typical ship presents a very large underwater surface, often as much as 3000 m2. To keep this amount of area groomed, a user could employ multiple HullBUG vehicles to operate at the same time using sophisticated coordinated navigation.

Navigating the HullBUG

A toolset of navigation modes has been created to let mul-tiple HullBUGs efficiently groom a ship by dividing the ship’s underwater surface into regions. Numerous algorithms have been incorporated to groom the ship accurately in steps down to the turn of the bilge. Additional algorithms and associated sensors are used to control efficient grooming on the flat bottom of the ship.

Miniature acoustic ranging sonar (MARS) is also an option for navigation control of the HullBUG. This is where a small, close-range pencil beam sonar was specifically developed to let the vehicle “see” an upcoming wall or cliff condition such as bilge keels and bow thrusters. Yet another mode of navigation uses a MEMS rate sensor for navigation information. Another feedback mode uses encoder-based odometry. Hall sensor feedback from the motor is used as an encoder signal to establish an accurate estimate of odometry. Hall sensors were used instead of optical encoders because of size and cost. The Hall sensors provide better than 1-mm accuracy in the measurement of odometry with the motor and gearhead combination chosen.

Ongoing Software Development

An autonomous vehicle is often software heavy in terms of engineering effort after having selected and implemented the proper motion-control system. Obtaining smooth, reliable navigation maneuvers that result in accurate posi-tioning in a widely varying environment was one of the more difficult challenges for the design team. Multiple layers of software were necessary for handling the number and variety of possible events that can occur during grooming. Also, the proper organization of the control logic to allow extensibility of navigation behavior was the most difficult part of this complex system.

“Software development will continue to be an ongoing effort even after the years already put into it,” says Holappa. “Though the vehicle is completely operational, there remains a considerable amount of on-ship testing to be done.” As the project moves forward and into the field, there will no doubt be additional issues that will crop up and need to be addressed. Even now, the vehicle must be able to accomplish its task reliably in a hostile environment and in an unmapped terrain. Then it has to be able to return to the waterline of the ship for retrieval. This operation must be done repeatedly for days, months, and years, and with multiple systems in the water at the same time.

Although this sounds as though it is overly difficult, according to Holappa, a technician was recently trained to use the vehicle and was fully competent in a short time. The user interface was borrowed from the SeaRobotics’ Unmanned Surface Vehicle (USV) product line, an intuitive graphics-driven interface that has logged hundreds of hours of use by many different customers. The next primary focus will be structuring the interface to improve ease-of-use and let non-engineering personnel manage operations.

For more information:

Maxon Precision Motor, Inc.

http://www.maxonmotorusa.com

SeaRobotics Corporation

http://www.searobotics.com

Filed Under: Encoders • optical, MECHANICAL POWER TRANSMISSION, Motion control • motor controls, Mechatronics

for ships such as 400m and above how much time this bug is going to take to clean the bio film properly

How do your machine handle the scrapings from the hull? How is it environment safe?