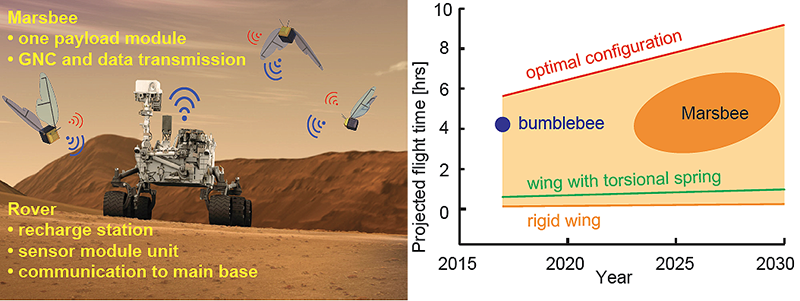

The objective of the proposed work is to increase the set of possible exploration and science missions on Mars by investigating the feasibility of flapping wing aerospace architectures in a Martian environment. The proposed architecture consists of a Mars rover that serves as a mobile base and a swarm of Marsbees.

Marsbees are robotic flapping wing flyers of a bumblebee size with cicada sized wings. The Marsbees are integrated with sensors and wireless communication devices. The mobile base can act as a recharging station and main communication center. The swarm of Marsbee can significantly enhance the Mars exploration mission with the following benefits: i) Facilitating reconfigurable sensor networks; ii) Creation of resilient systems; iii) Sample or data collection using single or collaborative Marsbees.

Key technical innovation includes the use of insect-like compliant wings to enhance aerodynamics and a low power design. High lift coefficients will be achieved by properly achieving dynamic similarity between the bioinspired insect flight regime and the Mars environment. Our preliminary numerical results suggest that a bumblebee with a cicada wing can generate sufficient lift to hover in the Martian atmosphere.

Moreover, the power required by the Marsbee will be substantially reduced by utilizing compliant wing structures and an innovative energy harvesting mechanism. Because of the ultra-low Martian density, the power is dominated by the inertial power. A torsional spring mounted at the wing root to temporarily store otherwise wasted energy and reduce the overall inertial power at resonance.

Whereas rotary wing concepts are much more mature in both design and control, these two innovations are uniquely suited to bioinspired flapping vehicles and provide flying near the Martian terrain as a viable means of mobility.

Graphic depiction of marsbee – swarm of flapping wing flyers for enhanced mars exploration. Credits: C. Kang

From a systems engineering perspective, the Marsbee offers many benefits over traditional aerospace systems. The smaller volume, designed for the interplanetary spacecraft payload configuration, provides much more flexibility.

Also, the Marsbee inherently offers more robustness to individual system failures. Because of its relatively small size and the small volume of airspace needed to test the system, it can be validated in a variety of accessible testing facilities.

The proposed work combines expertise and talent from the US and Japan in a multidisciplinary program to address fundamental aspects of flapping wing flight in Martian atmosphere.

The University of Alabama in Huntsville team will numerically model, analyze, and optimize a flapping flyer for Martian atmospheric conditions. The Japanese team will develop and test a micro flapping robot, uniquely designed and constructed for the low-density atmosphere on Mars. The hummingbird Micro-Air Vehicle (MAV), developed by the Japanese team is one of only a few robotic flappers in the world that can fly on Earth.

The objective of Phase I is to determine the wing design, motion, and weight that can hover with optimal power in the Mars atmospheric condition using a high-fidelity numerical model and to assess the hummingbird MAV in the Mars conditions.

The aerodynamic performance of the hummingbird MAV will be assessed in a vacuum chamber with the air density reduced to the Mars density. Systems engineering optimization will be performed as well for the entire mission. The maneuverability, wind gust rejection, take-off/landing, power implications, remote sensing, and mission optimization will be addressed in Phase II.

Filed Under: Aerospace + defense, Energy management + harvesting