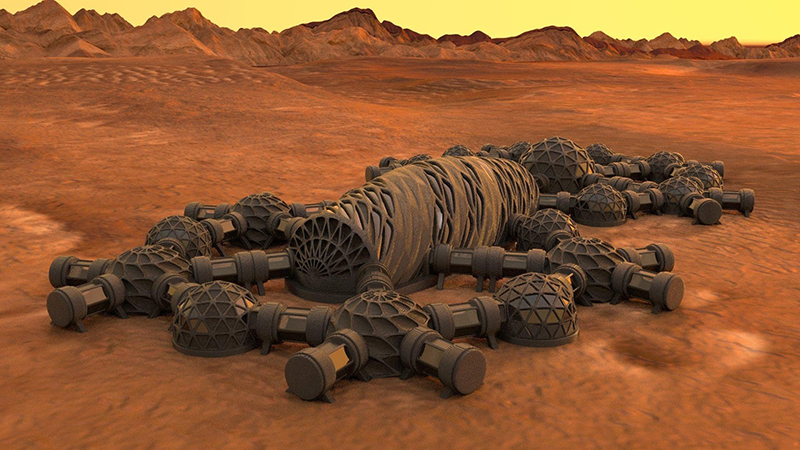

With multinational corporations competing against billionaire-backed startups to launch the first human mission to Mars, it seems inevitable that we’ll eventually see Earthlings attempting to colonize a new planet.

But once they boldly go where no human has gone before, how will these space explorers construct a place to call home?

It doesn’t make much sense to weigh down a spacecraft with terrestrial building supplies, so NASA’s Swamp Works lab is experimenting with 3D-printing habitable structures using a process called robotic extrusion, and a composite material made up of loose sediment (soil, dust, broken rock, etc.) and recycled plastic. The sediment, known as regolith, can be widely found on Earth, other planets, the moon, and even asteroids.

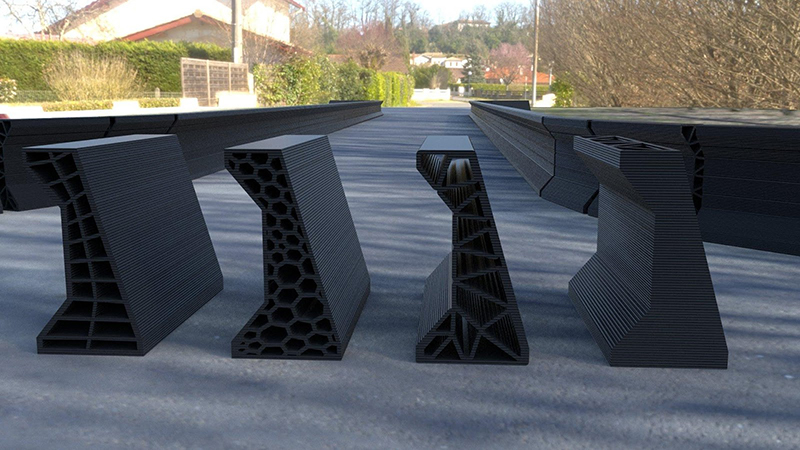

The first artifact that NASA has printed using this approach is a Jersey barrier – one of the modular barricades, typically made of concrete or plastic, that you often see separating lanes of traffic near road construction zones. In order to withstand vehicle impact, Jersey barriers must be tough and durable – characteristics that are desirable for human dwellings as well. So far, the regolith/plastic composite has proven to be strong and dependable, in addition to being relatively lightweight.

Based on NASA specifications, Autodesk’s Advanced Consulting team designed the barrier using tools such as Fusion 360 and PowerMill to comply with structural as well as robotic extrusion requirements while achieving significant weight reduction. Autodesk also developed the software to control the industrial robot arm – fit with a specialized end effector designed by NASA – to enable free-form additive manufacturing without the need for outside support or scaffolding.

“Additive manufacturing technology has the potential to revolutionize the way we do construction here on Earth, too,” said Massimiliano Moruzzi of Autodesk’s computational science research group. “If we can repurpose plastic pollution and use readily available natural resources to robotically print houses on Mars, we can use the same approach to sustainably build streets, sidewalks, and even playgrounds here at home.”

Click here to view video.

Filed Under: Aerospace + defense, Robotics • robotic grippers • end effectors