Battery-Powered Passive RFID is set to power new and emerging applications in manufacturing, supply chain, health care, asset management, security, and retail. For many applications, battery assisted passive effectively bridges the price/performance gap that exists between pure passive UHF and active RFID.

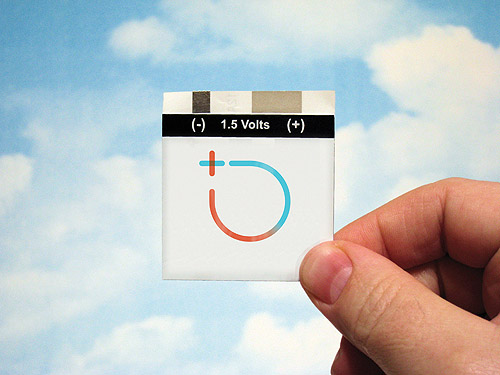

Battery Assisted Passive (BAP) RFID tags, also known as semi-passive tags, offer many of the same advantages of active tags, but at a lower cost. Typically, they include a small, eco-friendly, carbon-zinc battery to boost RF signal strength for longer read ranges and faster reads than pure passive RFID. The batteries can also improve read accuracy and reliability in environments such as those involving densely packed liquids or metals. Active RFID tags require a more powerful battery and are significantly larger, making them impractical for some auto-ID, security, asset tracking, manufacturing and supply chain compliance applications.

Most new BAP tags coming onto the market are fully compatible with the existing Gen2 RFID architecture, which lowers the cost of integration versus that of existing active systems. And, with a relatively simple architecture, BAP RFID tags can be manufactured in high volumes using conventional printing processes.

BAP tag characteristics make them a cost-effective and practical choice for many applications including: manufacturing and supply chain; healthcare, security and public safety; and retail.

Virginia-based NanoMarkets projects that RFID applications will be the dominant thrust in the thin-film and printed battery market, generating $4.6 billion by 2015, primarily because of the batteries‚’ relatively low cost, high-volume availability, and proven ability to improve RFID performance.

Blue Spark Technologies, Inc.

www.bluesparktechnologies.com

::Design World::

Filed Under: Medical-device manufacture, Power supplies, ELECTRONICS • ELECTRICAL

Tell Us What You Think!