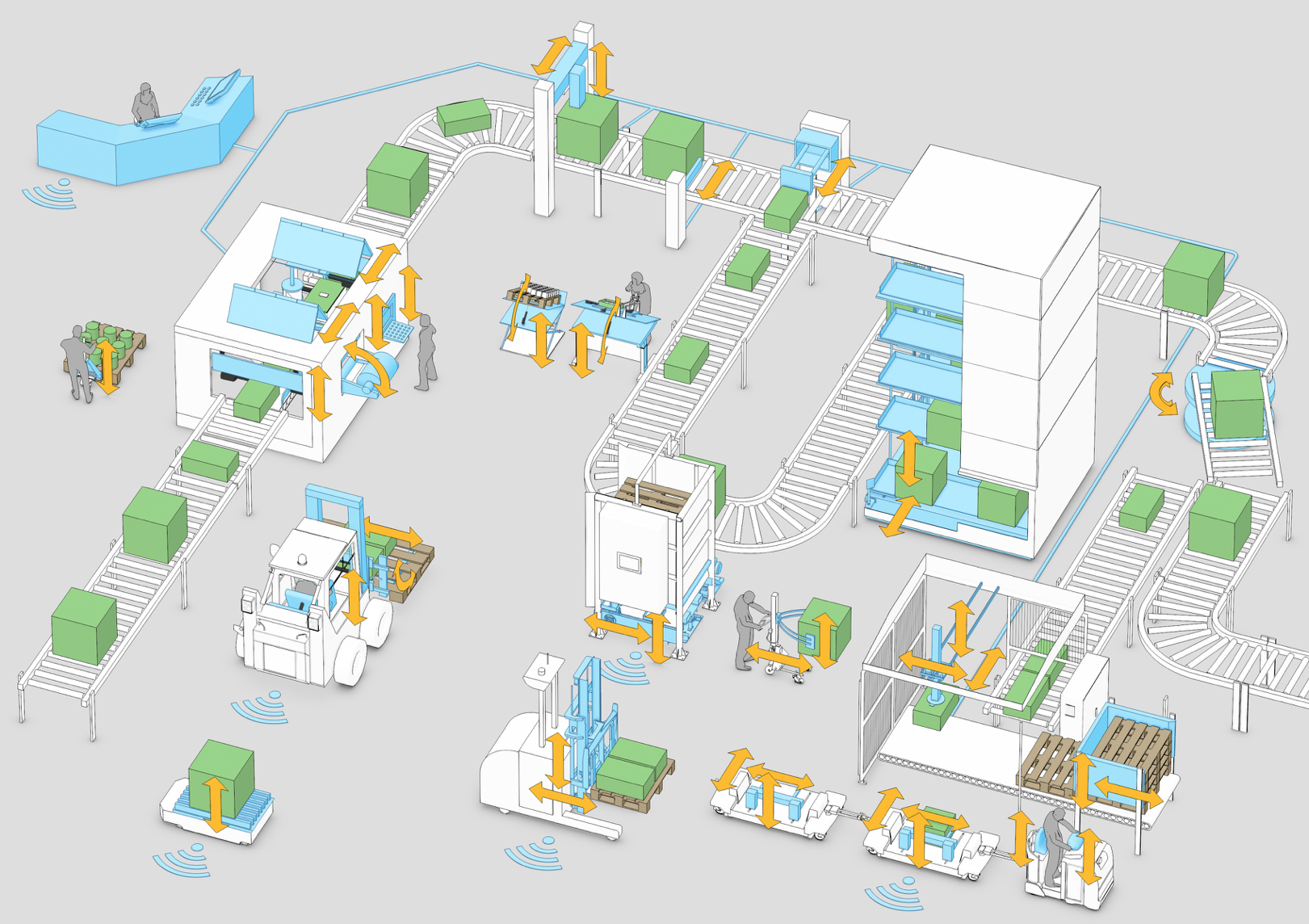

Thomson Industries, Inc., a leading manufacturer of mechanical motion control solutions, has published a new brochure that educates industrial automation users on the emerging role of smart actuators in meeting their demands for greater connectivity, application flexibility and cost efficiency. The brochure explores, with help from 10 pages of detailed 3D application renderings, the unique values to machine builders to be gained from smart actuators, their use in off-highway vehicles, factory automation and material handling. Also included are highlights of the Thomson Electrak® HD, Electrak Throttle, and WhisperTrak™ smart actuation products that deliver these benefits.

The new Thomson Smart Actuation Brochure

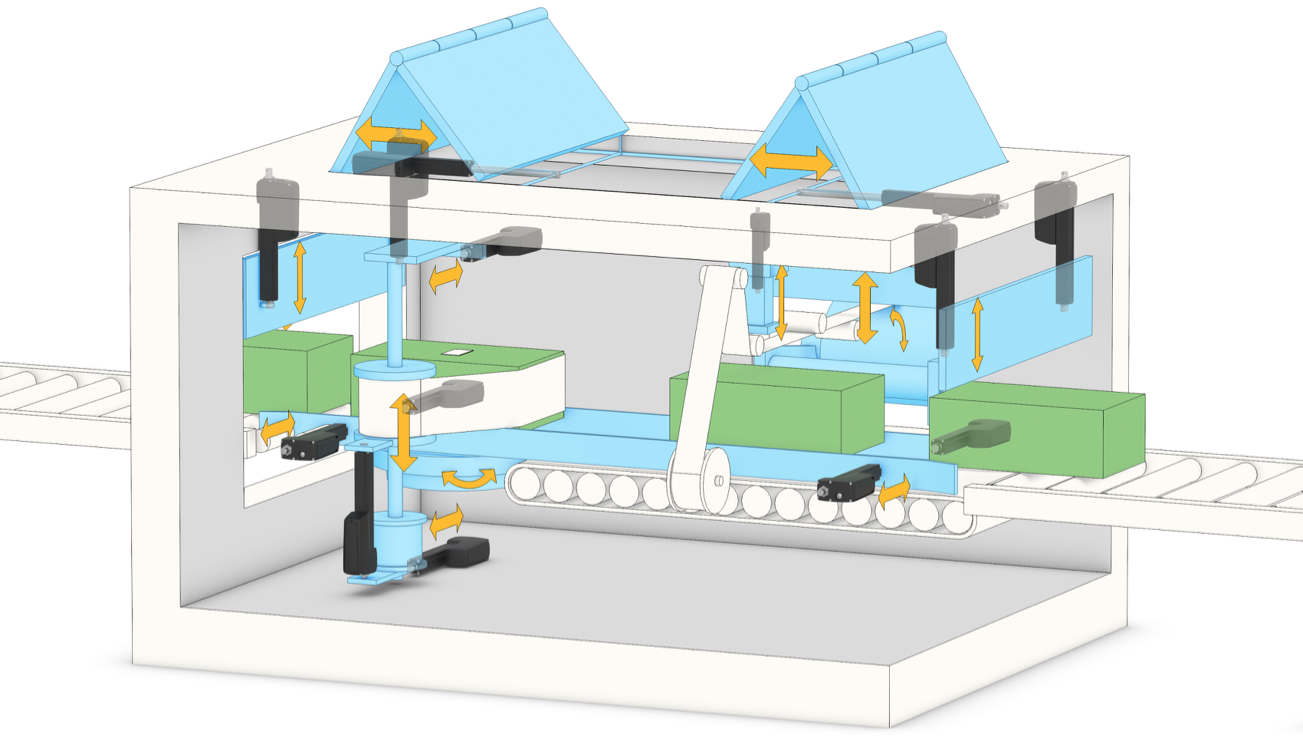

Titled Thomson Electrak Smart Linear Actuators (Electromechanical Solutions for Intermittent Duty Cycle Automation), the attractively illustrated 28-page brochure delves into the defining competencies of smart actuation. These include the ability to perform traditionally external control functions such as switching, position feedback and system diagnostics directly within the actuator housing, and support for J1939 network connectivity.

An interconnected factory using smart actuators in their machines benefits from reduced maintenance and downtime due to enhanced control capabilities and increased design flexibility.

Almost half of the document is devoted to how smart actuators deliver value to a widening range of industries, such as factory and structural automation, domestic, office and hospital equipment, material handling, and construction and agricultural equipment.

Once smart actuation is introduced into a facility’s automation process, the benefits are immediate and exponential. Machine design is simplified with increased flexibility and plug and play functionality, control capabilities are enhanced and energy usage is decreased.

The brochure also examines those Thomson actuators that meet the “smart” definition:

- Electrak HD linear actuators are high-powered solutions suitable for conversion from hydraulic to smart electric applications.

- Electrak Throttle linear actuators are optimized for easy-to-install and ergonomic engine speed control, based on the state of the vehicle.

- WhisperTrak linear actuators are quiet, small-footprint solutions ideal for medical, personal mobility, material handling, marine and structural automation applications.

A website dedicated to smart actuation can be found at www.thomsonlinear.com/smart.

Filed Under: Actuators, 3D printing • additive • stereolithography, CONNECTIVITY • fieldbuses • networks, LINEAR MOTION, Motion control • motor controls

Tell Us What You Think!