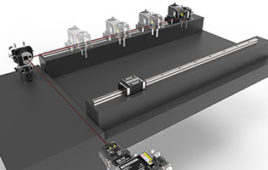

LinPerf™, short for Linear Perforation, is a new feature of the LASERDYNE S94P software. It provides an easy way to create programs that produce linear patterns of laser processed features on flat surfaces. The flat surfaces may be oriented in any plane accessible by the laser beam based on the number of axes and configuration of a LASERDYNE laser processing system.

LinPerf™, short for Linear Perforation, is a new feature of the LASERDYNE S94P software. It provides an easy way to create programs that produce linear patterns of laser processed features on flat surfaces. The flat surfaces may be oriented in any plane accessible by the laser beam based on the number of axes and configuration of a LASERDYNE laser processing system.

LinPerf is designed to take the hard work out of creating patterns with a laser system. Users provide information about the pattern such as hole spacing, orientation of the pattern, number of passes required to produce the holes, laser conditions, type of assist gas, and hole diameter or feature shape in the S94P graphical interface.

The S94P dialog box also displays calculated parameters including linear speed, hole elongation, and an estimate of run time for PosiPulse and MultiPulse modes. Calculated parameters are automatically updated when any inputs are changed. For example, linear axis speed is updated whenever the hole spacing or laser pulse frequency are changed.

An important feature of LinPerf is the ability to create programs for multiple, complex patterns drilled within a single row. The complex patterns are created by first defining simple, basic patterns and then combining the basic patterns in various ways to form complex patterns.

LinPerf is another exclusive and proprietary feature of the LASERDYNE product line that leads to laser processes with capabilities never before demonstrated. It is similar to CylPerf™ which is used for producing patterns of holes in cylindrical parts, such as aero-engine combustors.

“Our mission at Prima Power Laserdyne is to continue to produce advancements like LinPerf that help make our customers realize greater benefit from laser processing which ultimately helps them to be more successful,” stated Terry L. VanderWert, president of Prima Power Laserdyne.

LinPerf

www.primapower.com

Filed Under: ENGINEERING SOFTWARE, Lasers, MOTION CONTROL

Tell Us What You Think!