Vesconite Bearings is exploring new engineering design methods, including reducing or eliminating grooves, where possible, in industrial and marine applications.

Vesconite’s bearing materials are internally lubricated so, when replacing traditional materials, Vesconite is challenging engineers to explore designs that remove redundant or superfluous grooves for cooling lubricant or water.

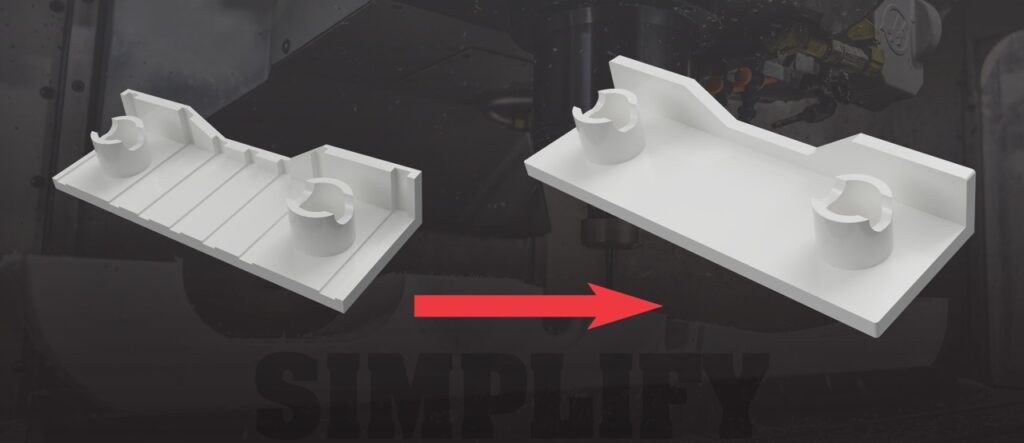

For instance, Vesconite engineers have redesigned a forklift lower wear pad without the seven grooves on the upper surface that were in place in the original molded nylon parts.

“Eliminating grooves improves the structural integrity of the part and reduces manufacturing times and costs,” says forklift application engineer Calvin Mpofu.

Similarly, Vesconite Bearings can better on previous marine stern-tube bearing designs where constant water cooling is needed and bushings have water circulation grooves.

“The number of grooves can be reduced where the groove radius and depth can be altered to obtain a sufficient flow of water for cooling,” reinforces marine application engineer Wian Venter.

As a result, Vesconite Bearings has suggested a reduction in the number of stern-tube grooves in a case where the original design was a rubber Cutlass bearing.

This original design, which included a nitrile rubber lining bonded to a brass shell, required many grooves running the length of the rubber lining to dissipate frictional heat and increase the cooling flow of water.

The alternative Vesconite Hilube design, without the brass shell and fewer grooves, improves the structural integrity of the stern tube and reduces manufacturing time and costs. Fewer grooves also mean that the total bearing surface in contact with the shaft journal is increased.

Most significantly, with Vesconite Hilube closer clearances can be machined than are achieved with rubber, so there is less shaft vibration.

For Mpofu and Venter, there is a clear advantage in rethinking existing designs and improving production methodologies and product durability.

They aim to make the engineering of Vesconite simpler, better, and faster.

Vesconite Bearings

www.vesconite.com

Filed Under: Uncategorized