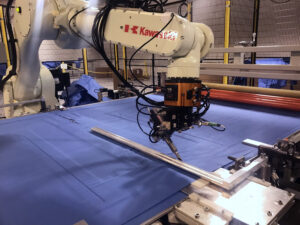

The ultrasonic welding horn end effector on the Kawasaki Robotics in this photo was designed by Harbour Technologies.

During the COVID-19 pandemic, the healthcare industry faced a large-scale personal protective equipment (PPE) shortage, putting frontline workers at risk of infection. Seeing this struggle, Ontario-based integrator and tool builder Harbour Technologies pivoted their business to include a new title — PPE manufacturer. Harbour Technologies designed a robotic cell to swiftly manufacture FDA-approved isolation gowns, helping the Canadian government provide more PPE to hospitals across the country. Now, because of their success, Harbour Technologies is setting its sights on providing PPE to the rest of the world.

“It’s tremendously important for Canada to have resilience in manufacturing PPE,” said Harbour Technologies co-owner Andrew Glover. “We saw it firsthand at the beginning of the pandemic when there was a shortage of PPE across North America … especially in Canada.”

Ensuring top quality with automated operations

Level-3 isolation gowns — those used by hospital staff during patient encounters involving blood draws, inserting intravenous lines, emergency and trauma treatment, and surgery — must meet extremely high FDA approval standards. The FDA demands that all areas of the surgical isolation gown except bindings, cuffs, and hems provide the highest liquid barrier protection level for which the gown is rated … necessitating tight quality control during gown manufacture.

“We teamed up with Kawasaki Robotics, which perfectly filled the need with their robots and continuous support,” said Harbour Technologies co-owner David Glover.“We sat with their engineering team, gave them the requirements, and worked together to select the proper robot and platform.”

“We found a lot of PPE was substandard and put frontline workers at risk,” said Glover. In contrast, automated gown production yields quality far superior to anything made manually, added Harbour Technologies co-owner, Andrew Glover. Harbour Technologies’ Kawasaki Robotics-based solution includes an RS050N robot installed to accomplish multiple tasks within the PPE manufacturing cell. The robot uses a tool-changing station to alternate between ultrasonic welding, knife, and gripper tools. It’s a scalable solution that will soon expand to 14 cells between two Harbour Technologies locations in Canada.

For Harbour Technologies, building an intuitive, easy-to-use system was also important — so their employees could operate the system freely. “We wanted to make sure that when an operator starts the machine, it does what it needs to do,” explained David Glover — so anyone can grab the pendant and start operating.

More details on the robotic operation

The robotic cell works like this: large rolls of the gown material are loaded into the cell. Servo-controlled rollers release the amount of material needed to produce one gown … and they can be adjusted on the fly to accommodate different products.

Once the tabletop workspace is covered in material, the Kawasaki Robotics robot goes to a tool-changing station to don a rotary ultrasonic welding horn designed by Harbour Technologies. Using this tool, the robot traces the gown profile to bond the front and back pieces of material together. Next, the robot swaps to a knife tool and traces the same path to cut sealed gown panels, neckties, and waistbands. Then, the robot dons a gripper to grasp the completed gown and set it aside for packing. Harbour

Technologies employees manually pack the gowns for distribution.

Harbour Technologies uses a Kawasaki RS050N robot (with a 50-kg payload and a 2,100 mm reach) customized to satisfy the intricacies of their PPE gown-making application.

Benefits to making the gown in a robotic system abound, according to Andrew Glover — including labor savings and cycle times … as his company can produce a gown a lot faster than what’s being made manually.

Automating gown production provides other advantages. The automated cell enables increased production while boosting product quality. Plus, this cell broadens Harbour Technologies’ business to become a global competitor in this space. What’s more, the company’s growth with robotic PPE manufacturing has created hundreds of jobs in their community.

“There was never PPE manufacturing in Canada at this level. With the robotic systems, it allows us to compete globally, which therefore creates jobs locally that were never there before,” said Andrew Glover. “Throughout Ontario, our productions are employing over 600 people, which was never there prior to the pandemic. Robotics allows us to continue creating jobs and growing in this market.”

Kawasaki Robotics USA Inc.

kawasakirobotics.com

Filed Under: Uncategorized