Rockwell Automation announced the addition of new energy intelligence capabilities in software applications. The new tools – the FactoryTalk VantagePoint Energy bundle, FactoryTalk EnergyMetrix software, and Allen-Bradley IntelliCENTER Energy software – help plant and operations managers view resource consumption in relation to specific units, lines and machines, so they can make more informed energy decisions. Energy intelligence is an extension of the manufacturing intelligence capability of turning data into information for informed decision making, by leveraging power and energy equipment as data sources.

FactoryTalk VantagePoint Energy Bundle

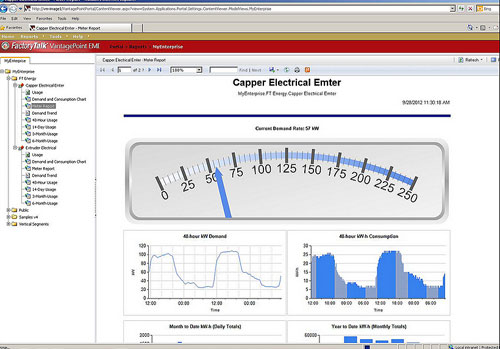

The FactoryTalk VantagePoint Energy bundle, which includes FactoryTalk VantagePoint EMI software plus energy-specific models, charts, trends, dashboards and analysis tools, provides access to more energy data. For current FactoryTalk VantagePoint users, an energy add-on can be purchased separately. With this application, users can aggregate metered energy-consumption data with production assets throughout the organization to start monitoring energy utilization.

Once energy utilization is better understood, users can explore behavioral changes to improve energy efficiency and reduce cost. Energy information from the asset level can be correlated with data from third-party control, process and business systems into one application, to not only improve energy efficiency but also overall production efficiency and revenue.

Plant managers and business leaders can easily access energy data, such as historical energy-cost trends or energy costs over time for a specific machine, line, plant or the entire enterprise via a web browser. FactoryTalk VantagePoint software users can now add energy intelligence to their manufacturing intelligence strategy, to access the data necessary to optimize energy consumption, correlate energy usage, determine cost to production, negotiate energy rates, and improve efficiency.

FactoryTalk EnergyMetrix Software

FactoryTalk EnergyMetrix software collects, records and stores energy data from Allen-Bradley or third-party power meters. The software can also capture information on energy usage, flow, temperature, and pressure from controllers, third-party devices or manual entries. With FactoryTalk EnergyMetrix software, users can set parameters that create alarms, and send human-machine interface and email alerts when energy-usage levels reach a user-specified level. This function can be crucial for manufacturers that receive energy bills based on peak kilowatt demand per day.

FactoryTalk EnergyMetrix software also trends historical data dynamically or within custom reports and charts. The application can compare alternative rate schedules to analyze potential cost savings, create energy budgets and forecasts, and track progress toward energy-saving goals against live data. Power-quality analysis capabilities allow users to better understand power quality and how it is affecting a specific line or facility.

IntelliCENTER Energy Software

A new option is now available for IntelliCENTER software – IntelliCENTER Energy. IntelliCENTER Energy software offers a preconfigured setup of FactoryTalk EnergyMetrix software for intelligent motor control devices in the motor control center, including variable speed drives, overload relays, and SMC controllers. Users can view real-time energy consumption and historical trending at the device level directly from IntelliCENTER software. With IntelliCENTER Energy software, it becomes easier to monitor and manage energy usage in the industrial facility for substantial cost savings, and allows for easy integration of motor control centers into plant wide energy management systems.

Rockwell Automation

www.rockwellautomation.com

Filed Under: Factory automation, ENGINEERING SOFTWARE, Energy management + harvesting

Tell Us What You Think!