By Michael Jermann/ Assistant Editor

When selecting a brake to control unbalanced or vertical loads, designers have a variety of choices ranging from simple locking devices to electrically or pneumatically powered units.

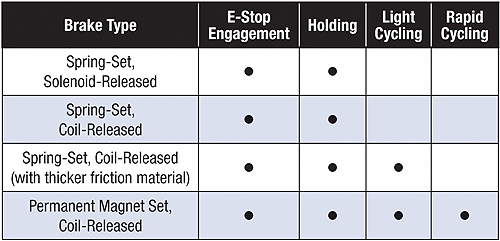

There are several types within the electrically released brake family. Some units are designed for occasional load holding usage. Others are developed for relatively high cycle rates and are designed to stop as well as hold the load.

Within the families of holding brakes there are two common designs: spring-set/solenoid- released and spring-set/coil-released units. In spring-set designs, either solenoid or coil released, the brakes function very much alike: When there is no power, springs compress the friction disc against the housing, holding the load stationary. When power is applied, the solenoid will engage or the coil will magnetically clamp a disc and compress the springs releasing the friction facing so that the load is free to rotate.

All of these spring-set brakes basically function the same: when power is applied, they will be disengaged or released; and when power is removed, they will engage or lock-up. Therefore, all spring-set brake designs meet the important task of engaging if power fails unexpectedly which will stop and hold a load stationary and safely.

Beyond the emergency stop function, solenoid-released designs are constructed as holding brakes not as cycling/stopping brakes. Depending upon load, speed and cycle rate it is not unusual to see these brakes requiring adjustment on a monthly basis to compensate for wear. It would be easy to denigrate these units as poorly designed, but the reality is that they are designed just fine, but they are often poorly applied. Many have been adapted into motors by motor manufacturers for a long time. Years ago, motorcycle rates and solenoid- released brake cycle rates were similar. Brake designs have simply not kept up as motor construction and insulation have improved and cycle rate capability have increased.

Within the coil-released brake designs, many spring-set, electrically released models are designed for holding or static engagement applications. When they are subjected to rapid stopping cycles they wear out quickly.

Electrically released breaks, one of the most common configurations, can be found either integrated into motors or as stand-alone units

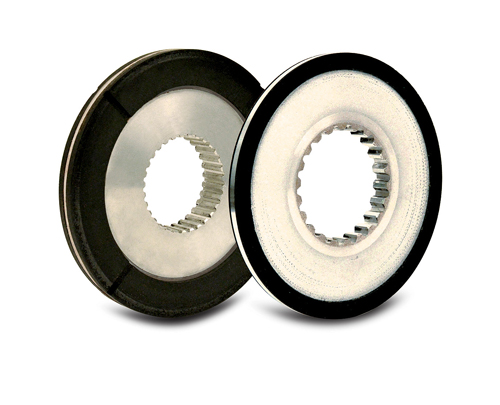

Some spring-set, electrically released brake designs compensate for wear by increasing the thickness and surface area of their friction facing so the key wear component will last longer under cycling applications. This added friction facing might be sufficient to provide adequate life in some lesser cycling applications.

Coil-released/permanent magnet set brake designs do not suffer from the wear life issues that spring-set designs do because they are designed for high cycle rates. The basic design for a permanent magnet, electrically released brake is the same as for an electrically engaged brake. Both are designed for long-life in rapid dynamic stopping applications. While more expensive than the simpler static engage designs, these units provide three to four times longer wear life than the static designs in cycling applications. As a result of their configuration, permanent magnet designs can include an airgap-adjusting feature so they require no wear adjustment throughout the life of the unit.

When choosing a power-off brake for an application it’s important to consider how the brake will be used. Static engagement units are commonly used in applications where a servo or step motor provides deceleration and stopping torque, but where the load needs to be held safely once it’s stopped. Vertical-mounted lead screw applications or loads that are unbalanced or eccentrically loaded are two common examples.

Proper selection of power-off brakes can make the difference between long life performance or recurring downtime and adjustment events

In both instances, the e-stop function is needed, but for most engagements the load will already be stopped and only need to be held. Properly applied, holding brakes will last almost indefinitely since they are engaging at zero speed and seeing little to no rotational movement.

Brakes designed for cycling are commonly found on declining conveyor systems in warehouse applications that may be subjected to dozens or even hundreds of stopping events per shift. The frequency of stopping events will determine if a low cycle rate or a high cycle rate brake is appropriate.

In many cases, the lowest purchase cost choice may result in the highest cost of usage and ownership.

Altra Industrial Motion

www.altramotion.com

Filed Under: Collars • locking devices, MOTION CONTROL, MORE INDUSTRIES

Hello dear

It is Hosein, an elecrical enginner in Metroplast company in Turkey (http://www.metroplastasansor.com.tr/) we want to buy friction dis,

may be you can help me.

Kind regard

Hosein

[email protected]

0090 534 7396139