On this day in history, October 7, 1913, Henry Ford and his team at the Highland Park automobile assembly plant in Michigan launched the first moving assembly line. It simplified and quickened the assembly of the Ford Model T’s 3,000 parts by breaking it into 84 steps performed by workers as a rope pulled the vehicle chassis down the assembly line.

Yesterday: Stalin Announces USSR Has Tested Atomic Bomb

The new system dramatically reduced the assembly time for each vehicle from 12 hours to approximately 90 minutes. Due to this reduction in time, Ford was able to drop the price of the Model T from $850 to less than $300. By 1927, more than 15 million Ford Model T’s were sold worldwide, accounting for half of all automobiles sold.

The rapid pace of production also allowed Ford to pay his workers higher wages. In 1914, Ford initiated the “$5 workday” to enable his employees to actually purchase the vehicles they manufactured.

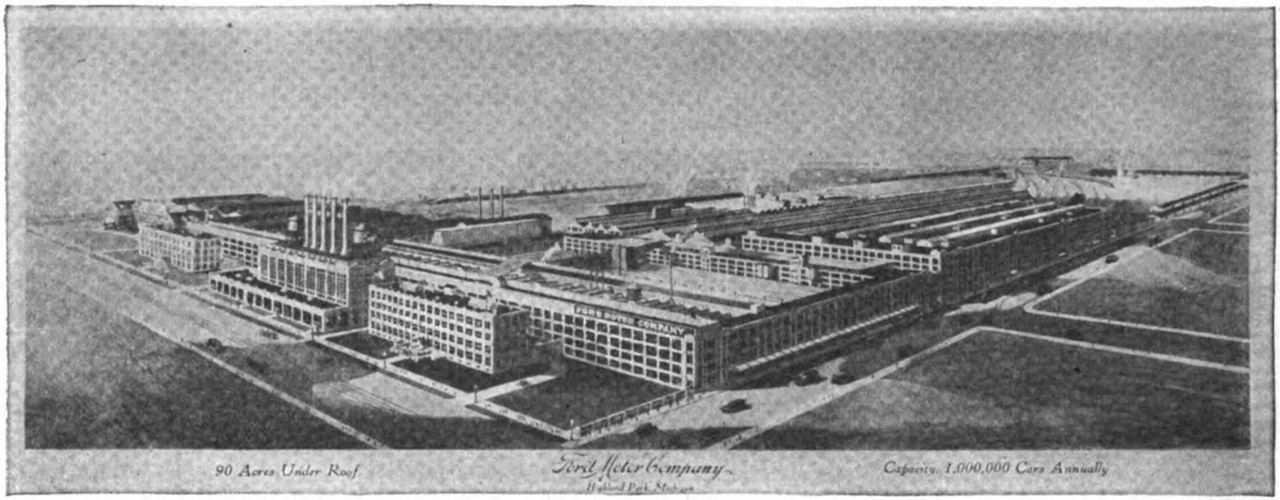

The Highland Park plant of the Ford Motor Company in 1922. Image credit: Bernard L. Johnson, Public Domain, Wikipedia Commons

The first Model T was introduced in 1908 and became a rapid success. Ford quickly realized that he would need to move out of the small Ford factory, on Piquette Avenue in Detroit, to a larger facility. He, therefore, bought 60 acres in Highland Park.

In addition to requiring a larger space, Ford also recognized that he would need a better method of manufacturing his vehicles. At the time, most manufacturers built cars one at a time, meaning the chassis stayed in one place during the entire assembly process.

Ford and his assistant Charles Sorensen started experimenting with methods to bring the work to the man, instead of bringing the man to the work. Initially, they tried supporting vehicles on movable benches that were pushed from one workstation to the next. The cars were still mostly handmade, but the process did speed up production.

The Highland Park Ford plant, circa 1922. Image credit: Public Domain, Wikipedia Commons

In April 1913, a production engineer in the flywheel magneto assembly area attempted a novel way of putting his component’s parts together. He had divided the operation into 29 steps, in which workers placed only one part in the assembly before pushing the flywheel to the next employee. This breakthrough inspired a full-fledged moving assembly line, which was launched on October 7, 1913.

Workers on the first moving assembly line put together magnetos and flywheels for 1913 Ford autos in Highland Park, Michigan. Image credit: Public Domain, Wikipedia Commons

The rudimentary assembly line pulled a chassis across the factory floor by a rope and windlass. Vehicle parts and 140 workers were stationed along the 150-foot line to attach parts as the winch dragged the chassis along the floor. By using the system, production time for one vehicle dropped from about 12 hours to just under six hours.

The method was improved with a power-drive “endless” conveyor system, and by 1914 the time to assemble one vehicle fell to about 90 minutes.

Filed Under: Industrial automation