One way to improve productivity numbers is to keep fork truck drivers on their trucks. The Click-n-Go™ wireless remote control does that by enabling drivers to simply place a pallet load on the stretch wrapper, back away a few feet and press a button to start the stretch wrapping process. It also gives operators more flexibility by eliminating the need to stop within reach of a lanyard, the other option often used for remote start.

The control is more than a remote start button. It is capable of controlling multiple machines. Plus, an additional feature button initiates a banding sequence for double-stacked pallets. Click-n-Go now gives the customer more flexibility in how the machines are used or relocated, plus, it meets current safety codes.

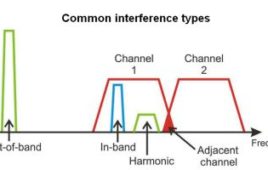

Using line-of-sight transmission and a two-step activation process, it is immune to interference or accidental activation from stray radio frequency interference. Safety is assured by requiring two buttons be depressed in sequence for each machine activation: the “arm” button initiates visual and audible alarms at the machine, followed by pressing the “start” button.

Click-n-Go exploits the advantages of Lantech’s Simple Automation stretch wrappers equipped with XT cut and clamp that automatically starts the film on each load and cuts/holds the tail of the film after wrapping. The Simple Automation machines — Q300XT, Q300XT Plus, Q-400XT and S300XT — keep the operator on the lift truck for maximum productivity.

Lantech

www.lantech.com

::Design World::

Filed Under: Wireless • 5G and more, Material handling • converting

Tell Us What You Think!