by Mary C. Gannon, Senior Editor

Enable consistent, strong and more efficient structures with friction stir welding.

Traditionally, joining two separate pieces of metal requires a filler material, usually an alloy different from the base metal. For example, MIG and TIG welding is most common in the aluminum extrusion industry, but in some cases, adding this different alloy can cause miniature stresses as well as corrosion problems down the line.

Friction stir welding (FSW), still a relatively new technology, has seen an increase over the last several years in its end-use application, said Jason Weber, the director of business development for energy and industrial products of SAPA Extrusions North America.

Invented in 1991 by the Welding Institute of Cambridge, it is mostly used in the aerospace and defense industry, but continues to broaden its range of end use applications, such as in the rail, marine and energy sectors, said Steve Jackson, business development manager for thermal management at Sapa North America.

FSW is a method of joining two pieces of metal with no filler metal involved at all, subjecting components to heavy plastic deformation at high temperatures. “The key point here is [the process] is lower than the melting point. The process itself uses a rotating tool that is plunged into the components and friction is generated,” said Jackson. “It really is that simple. The tool produces a severe plastic deformation under high pressure, which welds the two materials together.”

Example of FSW used for cold plate manufacturing.

How it works

Jackson said that the weld probe and fixturing is critical in FSW. When joining two pieces of aluminum, the weld probe generates heat through friction, creating a homogenous structure.

“Because aluminum has naturally high thermal properties, the heat actually is naturally pulled away from the weld probe so you get the fine microstructure,” Jackson said.

Unlike the mostly handheld manual MIG and TIG applications, FSW is always done by a machine that provides a consistent, high-quality finished product.

One of the biggest questions is why use FSW in the first place? FSW can transform small extrusions into wide extrusions. The typical aluminum extrusion press in the U.S., as well as worldwide, has a 7-in. circle size. Some companies are fortunate enough to have larger presses ranging up to 24 in. in diameter; however, the bigger the circle size, the higher the costs. The typical maximum width is 48 in.; however, the same technology is used to weld train frames together creating the body, which can have a 20-ft radius.

Why it’s better

When performing MIG or TIG welding, you need to use an inert gas to prevent contaminants from entering the weld. As the weld melts and reaches its boiling point, you need to ensure that no contaminants get into the weld. Contaminants lead to porosity, which then cause problems from a thermal management and stress point of view. This is not a problem with FSW, because porosity is not an issue, so leaks and areas where miniature cracks can develop are eliminated.

Example of FSW used in the manufacture of trains.

Additionally, FSW offers reduced thermal distortion and shrinkage because the material never gets to the melting point. It also provides improved repeatability and is suitable for automation. And, if an application requires two different alloys—for example, brass and aluminum—they still can be welded together.

Modular versus bonded fin heat sinks

FSW of aluminum extrusions is being used more and more to take advantage of the excellent thermal properties of aluminum. Aluminum is used worldwide in large heat sinks because it offers high thermal efficiency and no porosity. It is also easy to manufacture aluminum into custom shapes, is lightweight and has low material costs. Although copper may have better thermal properties, its inconsistent price points inhibit its wider use. In addition, copper is heavier than aluminum and cannot be extruded.

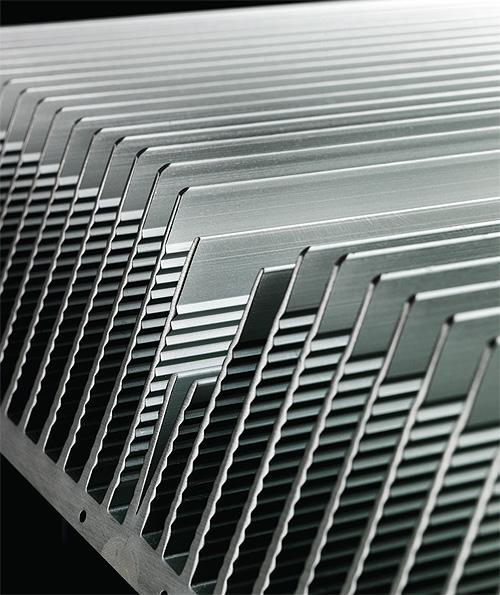

Example of FSW to create wide heat sink.

Extruded aluminum offers a mix of advantages and disadvantages. For example, said Jackson, extrusions are superior to castings and bonded fin heat sinks and is available for total lower cost. The challenge comes, however, because typically in North America, aluminum extruders go up to about 4:1 ratio or even 10:1 ratios. Just a handful of aluminum extruders, SAPA included, can extrude fin ratios up to 16:1 and occasionally 19:1. Previously, this met most thermal applications; however, as electronics continued to get hotter, the thermal management industry developed bonded fin heat sinks. Bonded fin heat sinks can reach ratios of 40:1; however, this process is labor intensive and requires products to be “super-glued” together with thermal epoxy.

An example of a modular heat sink manufactured with FSW.

To reduce labor costs, SAPA developed its own modular heat sinks that offer ratios up to 60:1. Through testing, the company was able to prove that FSW module heat sinks are 8% thermally more efficient than bonded heat sinks because there is no filler material, like the thermal epoxy.

Cold plates are yet another example of advanced thermal technology using FSW, especially in vehicles. Previously, cast cold plates were used, however porosity on large castings proved to be expensive. FSW is used to weld end caps on the extruded cold plate. Recent tests showed the product withstood pressure testing up to 2,700 psi.

Jackson stresses the importance of working closely with the design engineers at your extruder or thermal management company early because thorough and proper extrusion design can reduce the weight, while increasing function and operation.

“You want to really make sure you’re using the best practices for manufacturing. You want to design the extrusion so that it can be friction stir welded as fast and as easily as possible,” he said. “Regarding a thermal performance, make sure you’re using the correct alloy as well as the fin design and the heat sink orientation. When you put all of this together, you can get an efficient, cost-effective solution.”

Conclusion

In conclusion, FSW is an alternative to other welding and mechanically joining methods used to join both aluminum extrusions and other alloys together. The automated process can be applied to aluminum extrusions as well as for joining extrusions to other materials. The result is a product stronger and thermally more efficient than MIG, TIG or bonded fin heat sinks.

SAPA Extrusions North America

www.sapagroup.com

Filed Under: FASTENING • JOINING • locks • latches • pins, Materials • advanced

Tell Us What You Think!