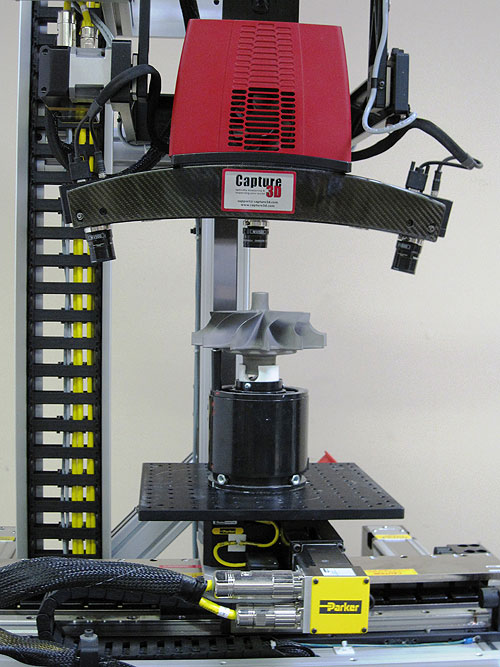

Portability is an important feature in 3D scanning equipment. The MC-XL and MC-SO 3D scanners are built at the Costa Mesa, Calif., headquarters of Capture 3D Inc. Engineered for the aerospace and automotive industries, the larger MC-XL handles parts up to 300 lb, while the smaller MC-SO handles parts weighing 30 lb or less, which is suitable for the consumer industry. Both versions rely on Ethernet Powerlink (EPL) controllers and Aries EPL servo drives, from Parker Hannifin, to precisely control the multi-axis motion.

Ethernet Powerlink’s ability to precisely deliver motion commands enables this 3D scanner to gather data on an impeller.

Each scanner uses six axes and two cameras to acquire an object’s data — everything from measurements to physical characteristics. The process requires precise position control of the six motion axes to preserve the integrity of the data acquired by the Advanced Topometric imaging sensor, or ATOS, as it moves around the part.

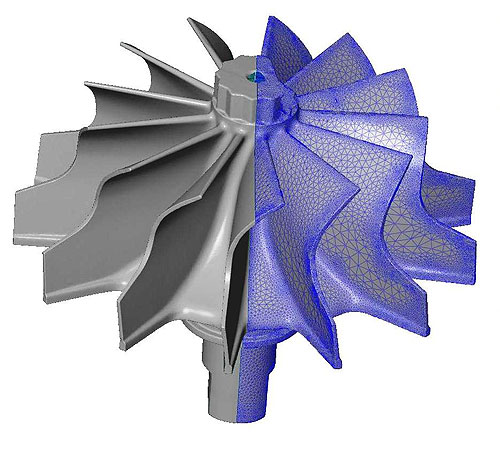

The scanners use the principles of triangulation. The two cameras observe projected fringe patterns. A microprocessor calculates three-dimensional coordinates for each camera pixel. Finally, a polygon mesh of the object’s surface is then generated. A customer may ultimately use this descriptive data of the objects skin for pass/fail inspection of a first article, for further analysis of a rapid prototype, or for reverse engineering a mold to duplicate a hand fashioned or one-of-a-kind part.

The EPL-enabled products deliver real-time, deterministic motion control commands over standard Ethernet hardware. The Ethernet cabling simplifies installation, increases reliability, reduces set-up time and shrinks the required panel footprint. Because EPL systems require less space than traditional analog controls, the MC-XL and MC-SO are able to go where other scanning machines cannot.

The scanning software integrates easily with the ACR controller. The flexibility to use internal programs that can be controlled remotely delivers an automated, easy-to-use measurement system to clients. They can develop automated processes with no prior knowledge of motion control systems.

Parker Hannifin

www.parkermotion.com

Capture 3D Inc.

www.capture3d.com

::Design World::

Filed Under: Aerospace + defense, Digital manufacturing, Ethernet — cables • hubs • switches, CONNECTIVITY • fieldbuses • networks, Automotive, Motion control • motor controls

Tell Us What You Think!