ABB is expanding its range of SCARA robots with the launch of the IRB 920T. Designed to meet the requirements of the electronics industry for high-speed production in increasingly complex manufacturing processes, the IRB 920T provides the highest levels of speed, accuracy and repeatability for assembly, picking and handling tasks.

“The need for companies to respond quickly to changing consumer demands is making SCARA robots a popular choice for production lines where fast and accurate performance is key to ensuring maximum product quality,” said Antti Matinlauri, head of Product Management for ABB Robotics. “Together with ABB’s OmniCore controller, the IRB 920T is part of a new generation of robotic solutions from ABB that help manufacturers stay one step ahead of changing market demands.”

With a cycle time of 0.29 seconds, the IRB 920T is faster than other SCARA robots in its class and up to 14% faster than ABB’s current IRB 910SC SCARA robot, enabling more products to be produced per hour. With a maximum payload of 6kg and available in a choice of variants offering reaches of 450, 550 and 650 mm, it can be installed throughout production lines to handle a variety of items, from single components through to assembled products.

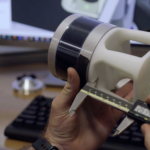

Key to the performance of the IRB 920T is its excellent repeatability. Offering class-leading consistency, the IRB 920T can work quickly without the risk of errors, making it possible to achieve the highest levels of manufacturing quality with minimal or zero wastage. This flexibility is further supported by its lightweight and space-saving design. Weighing just 24 kg, the IRB 920T is 10% lighter than other SCARA robots in its class, reducing cell design costs by eliminating the need for extra materials to support the robot. With all cables routed internally to remove cable interference, it also offers a compact footprint, enabling optimization of available production space.

ABB

www.abb.com

You may also like:

Filed Under: Robotics • robotic grippers • end effectors