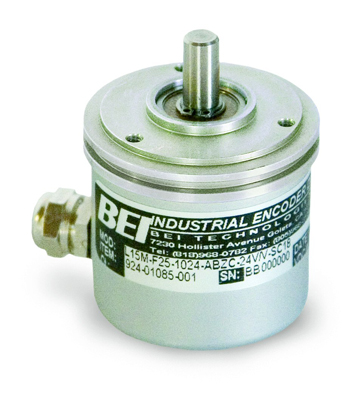

BEI’s compact L15 incremental encoder measures 1.5 in. in diameter and gives up to 40,640 cycles per turn. Internal, electric multiplication increases output resolution up to 16 times without degrading overall encoder accuracy. By using the standard quadrature detection option available on most PLC’s, counters, and controllers, a maximum of 162,560 counts is available.

Ideal applications for this high resolution, compact encoder include semiconductor fabrication and industrial robotics.

It has a 15 servo-mount style package, 1/4 in. diameter stainless steel shaft, and can handle up to 5 pounds radial or axial load. The encoder package has field-proven ASIC electronics, sealed dual bearings, and BEI’s accurate code disk in an all metal housing.

For more information, visit: www.beiied.com/PDFs2/L15_Incremental_Encoder.pdf

BEI Industrial Encoders (IED)

7230 Hollister Avenue

Goleta, California 93117-2891

Tel: 805-968-0782 or 800-350-2727

Fax: 805-968-3154 or 800-960-2726

Web: www.beiied.com

About BEI

BEI Industrial Encoders (IED) is an operation of Custom Sensors & Technologies (CST). IED manufactures optical encoders and associated electronics for the industrial market. IED is the market-leading brand of encoders in North America.

Custom Sensors & Technologies (CST)

14501 Princeton Avenue

Moorpark, CA 93021

Tel: (805) 552-3599

Fax: (805) 552-3577

E-mail: [email protected]

Web: www.cst.schneider-electric.com

About Custom Sensors & Technologies

Custom Sensors & Technologies (CST) is a business unit of Schneider Electric. CST provides sensors, controls, and actuation products to the industrial, transportation, military, and aerospace markets.

Head office Schneider Electric SA

43-45, boulevard Franklin- Roosevelt

92500 Rueil-Malmaison – France

Tel: +33 (0) 1 41 29 70 00

Fax: +33 (0) 1 41 29 71 00

Web: www.schneider-electric.com

About Schneider Electric

Through its brands, Merlin Gerin, Square D and Telemecanique, Schneider Electric satisfies its customers’ requirements in the residential, building, industry, energy, and infrastructure markets.

Filed Under: Aerospace + defense, Factory automation, Semiconductor manufacture, Encoders • optical, Encoders (rotary) + resolvers, Packaging, Motion control • motor controls

Tell Us What You Think!