By Adam Willwerth, Electro Static Technology

Nearly all VFD-driven motors are vulnerable to bearing damage, but for too long the importance of shaft grounding to protect motor bearings has been ignored or underestimated. To make the savings generated by VFDs sustainable, an effective long-term method of shaft grounding is essential.

All major manufacturers of 3-phase ac induction motors offer “inverter-duty” or “inverter-ready” models, but while these motors have inverter-rated insulation to protect the windings, the bearings — their most vulnerable parts — are too often ignored. The National Electrical Manufacturers Association (NEMA) has yet to recommend that new motors have bearing protection against damaging electrical discharges.

It is common knowledge that inverters, also known as variable frequency drives (VFDs) and adjustable speed drives, can induce unwanted motor shaft voltages that, without effective mitigation, can destroy bearings, causing premature motor failure.

Although current NEMA standards highlight the possible need for extra bearing protection for VFD-driven motors, the language is often not specific enough to guide motor manufacturers and has not been updated to include new research results and developments in shaft grounding technology.

Elusive sustainability

VFDs can save 30% or more in energy costs. Because of this, they have been cited as a key technology for those wishing to make their commercial HVAC systems, automated assembly lines, and other processes more energy-efficient (“green”). But, whether used to control a motor’s speed or torque, VFDs can induce voltages and currents that can damage bearings. In fact, the costly repair or replacement of failed motor bearings can wipe out any savings that a VFD yields and severely diminish the reliability of an entire system. And, when a VFD-controlled motor fails, warranty claims against motor and VFD manufacturers may not pan out. Because systems that use VFDs are so varied, the liability question is a hot potato.

Advances in bearing grounding technology

In nearly every case, the most reliable and cost-effective way to minimize electrical bearing damage and make these systems sustainable is a motor shaft grounding ring (combined with insulation for motors greater than 100 hp).

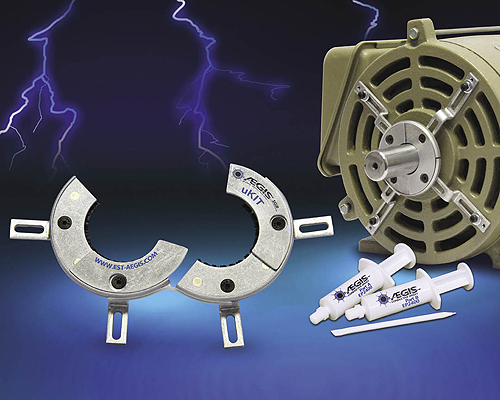

Unlike older single-point contact brushes, new grounding rings encircle a motor’s shaft with contact points. One model, the AEGIS® SGR Bearing Protection Ring, has continuous circumferential rows of specially engineered microfibers to boost electron transfer rates and provide very low impedance from shaft to frame. These rings safely bleed damaging currents to ground, bypassing a motor’s bearings entirely. And because the microfiber brushes work with little or no contact, they do not wear out like conventional brushes. AEGIS® rings have proven effective in over half a million installations worldwide.

Recognizing that the best solution is to design motors from the ground up to survive the damaging effects of VFDs, a few forward-looking motor manufacturers have recently added the AEGIS® ring as a standard or optional feature on certain models.

For example, Baldor Electric Company (now part of the ABB Group) has introduced a line of inverter-ready Super-E® NEMA Premium® motors with the AEGIS® ring installed inside. These include conveyor motors for airport baggage handling systems and other materials handling; and general-purpose and brake motors for machinery in many manufacturing applications. Baldor offers models from 1 to 100 hp in open drip-proof (ODP) and totally enclosed fan-cooled (TEFC) configurations with the AEGIS® bearing protection factory installed.

In addition, General Electric equips its A$D Ultra Constant Torque Variable Speed Drive Motors (1.5 to 300 hp) with internally mounted AEGIS® rings and offers the ring as an externally mounted option on its Energy Saver® ODP and TEFC motors. These motors are designed for metal processing, material handling, and other tough-duty applications.

But these motors are exceptions to the rule. And while many motor manufacturers will, at a customer’s request, add AEGIS® rings to their motors before shipping them, for motors already in service the rings must be retrofitted by the customer or contractor.

How VFDs cause motor failure

Damage to windings and bearings alike is caused by repetitive and rapid pulses applied to the motor from a modern VFD’s non-sinusoidal power-switching circuitry. The names used to describe this phenomenon include harmonic content, parasitic capacitance, capacitive coupling, electrostatic buildup, and common mode voltage. Regardless of the name used, high peak voltages and fast voltage rise times can cause cumulative degradation of insulation, bearings, coil varnish, etc. If the load impedance is higher than the line impedance, current is reflected back toward the VFD, creating voltage spikes at the motor terminal that can be twice as high as the dc bus voltage.

The cumulative bearing damage caused by VFD-induced currents is often overlooked until it is too late to save the motor.

Types of bearing damage

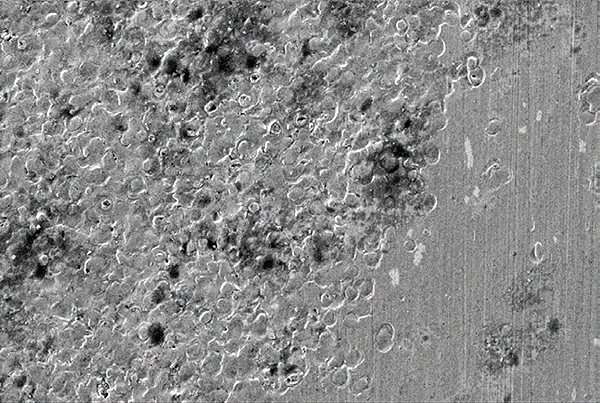

Without some form of mitigation, shaft currents discharge through bearings, causing unwanted electrical discharge machining (“EDMing”) that erodes the bearings and race walls [Figure 1] and leads to premature bearing/motor failure. Before long, these frequent discharges can leave the entire bearing race riddled with pits known as frosting [Figure 2]. In fact, electrical damage has become the most common cause of bearing failure in VFD-controlled AC motors.

[Figure 1] Viewed under a scanning electron microscope, a new bearing race wall is a relatively smooth surface, marked by nothing but mechanical wear where bearings contact the wall.

[Figure 3] Taken from a failed motor, the “fluted” bearing race wall (left) resulted from VFD-induced bearing currents. Protected by an AEGIS® SGR Bearing Protection Ring, the race on the right is undamaged.

In its role as information provider, NEMA is in the unique position to update its MG1 standard to more clearly state that common mode shaft voltages are present in nearly all motors fed by pulse-width-modulated (PWM) VFDs. Since no other entity is in such a position of authority, NEMA could at the same time address the overall problem of electrical bearing damage more clearly and firmly.

The association’s current standards acknowledge the potential damage from VFD-induced voltage spikes. The standards state that motors controlled by modern VFDs containing insulated gate bipolar transistors (IGBTs) should be designed to withstand repeated spikes (at the terminals) of up to 3.1 times the motor’s rated voltage, at rise times not less than 0.1 microsecond. Yet, when addressing the potential for bearing currents the language is far less prescriptive.

NEMA Standard MG1-2009 (Revision 1-2010), Section IV, Part 31, Definite-Purpose Inverter-Fed Polyphase Motors, correctly states: “Shaft voltages can result in the flow of destructive currents through motor bearings, manifesting themselves through pitting of the bearings, scoring of the shaft, and eventual bearing failure.”

Subsection 31.4.4.3 of Part 31 recommends bearing insulation at one end of a larger motor (defined as “usually 500 frame or larger,” horsepower unspecified) if the peak shaft voltage is greater than 300 millivolts. Unfortunately, the paragraph dealing with these larger motors only mentions circulating end-to-end shaft currents caused by magnetic dissymmetries under sinusoidal operation. It fails to add that the bearings of large motors can also be plagued by VFD-induced, high-frequency capacitively coupled common mode voltages.

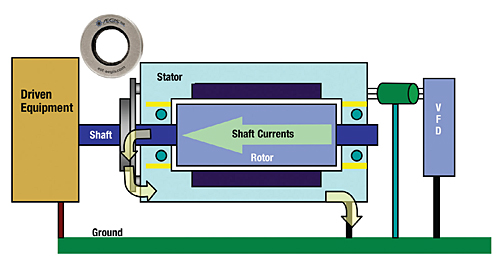

In a paragraph on “much smaller motors” (frame size and horsepower unspecified), the same subsection recommends insulating both bearings or installing shaft grounding brushes to divert damaging currents around the bearings. For these motors, the standard correctly explains, a VFD can generate high-frequency common mode voltage, which shifts the three-phase-winding neutral potentials significantly from ground. Because the damaging voltage oscillates at high frequency and is capacitively coupled to the rotor, the current path to ground can run through one bearing or both. But here the standard neglects to mention that high-frequency circulating currents may also be present in VFD-driven motors as small as 100 hp.

To summarize, NEMA omits common mode voltages from its paragraph on larger motors and omits circulating currents from its paragraph on smaller motors. Another problem with NEMA’s current language is that neither a grounding brush nor insulation is a reliable, long-term solution to the problem of electrical bearing damage at the system level, which includes motors and attached equipment.

To its credit, the NEMA standard does correctly point out that “insulating the motor bearings will not prevent the damage of other shaft connected equipment.” When the path to the bearings is simply blocked by insulation, the damaging current seeks another path to ground. That other path can go through a pump, gearbox, tachometer, encoder, etc., which consequently can end up with bearing damage of its own. The economical solution, of course, would be a maintenance-free, long-life shaft grounding ring that protects attached equipment as well as the motor’s bearings.

Best practices to mitigate bearing damage

When designing a true inverter-ready motor, a manufacturer should strive to protect the motor’s bearings as well as its windings. Stronger NEMA standards would be an incentive for built-in bearing protection that extends motor life. The following measures have proven effective under actual operating conditions and should be considered for inclusion in any NEMA standards updates:

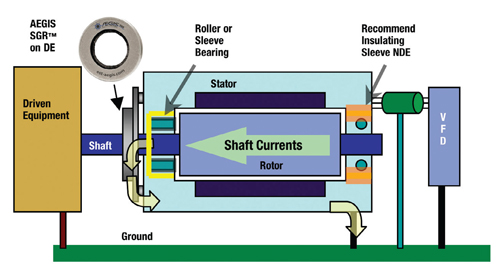

• For motors above 100 hp, where both circulating currents and common mode voltages could cause bearing damage, combining an insulated bearing on one end with a shaft grounding ring on the opposite end provides the best protection from electrical bearing damage [Figure 4].

[Figure 4] For motors above 100 hp, both circulating currents and common mode voltages can cause bearing damage. Combining an insulated bearing on one end with a shaft grounding ring on the opposite end provides the best protection from electrical bearing damage.

[Figure 5] For motors up to 100 hp, where common mode voltages could cause bearing damage, adding a shaft grounding ring to the motor, either inside the motor or externally, provides effective protection against bearing currents for motor bearings as well as attached equipment.

Other devices that may provide a path to ground fall short of the AEGIS® ring. None of them work as well as the AEGIS® ring at high rpms. And although the primary reason is that they wear out faster, there are other reasons for their reduced effectiveness — reasons that limit the effectiveness of all “single-point contact brushes.”

Metal spring-pressure grounding brushes, for example, are easily contaminated by corrosion or clogged by debris, requiring regular maintenance/replacement.

Carbon-block (graphite) brushes have an additional drawback. They are susceptible to “hotspotting,” in which an arc briefly fuses the brush to the motor shaft. And other “contact” brush designs quickly wear out, with the result that shaft currents return to discharging in the bearings.

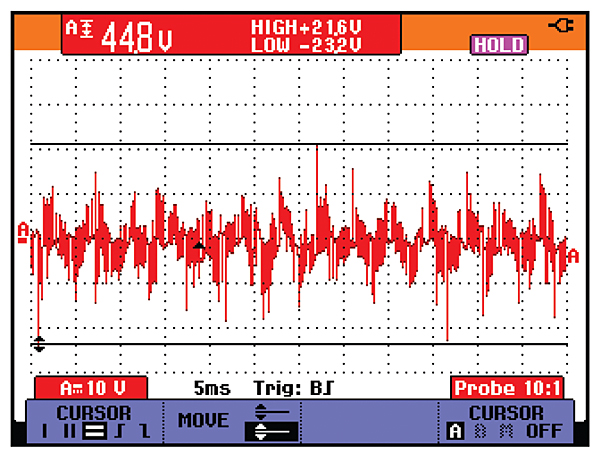

The above configurations have one thing in common — they rely on direct contact to transfer current. The AEGIS® ring, however, is unique in that it works both with contact and also without direct fiber contacting the motor shaft. Its contact/non-contact Electron Transport Technology™ discharges shaft voltages even if its fibers are not touching the motor shaft. And because it works without contact, the AEGIS® ring will not wear out and requires no maintenance, regardless of rpm. Its patented technology makes it an effective device for redirecting currents from shaft to ground [Figure 6]. Easily installed at the factory or retrofitted later [Figure 7], it makes VFD-controlled systems sustainable by protecting motor bearings from catastrophic failure.

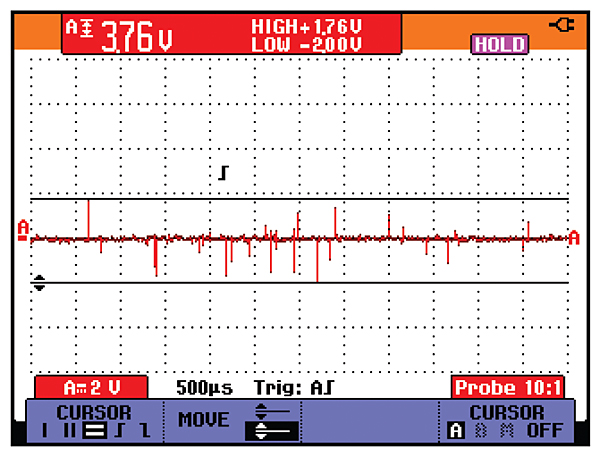

[Figure 6] Measured with an oscilloscope, motor shaft currents before (top) and after (bottom) installation of the AEGIS® SGR Bearing Protection Ring on a motor in an HVAC unit.

Key to the AEGIS® ring’s capability is the proprietary conductive microfibers that completely surround the motor shaft. Secured in the ring’s patented FiberLock™ channel, these fibers can flex without breaking, and the deep protective channel keeps them away from dust, liquids, and other debris. Testing shows surface wear of less than 0.001 in. per 10,000 hours of continuous operation and no fiber breakage after 2 million direction reversals.

[Figure 7] The AEGIS® SGR Bearing Protection Ring is available for any size NEMA or IEC motor. It can be factory-installed inside new motors (as with the Baldor Super-E® NEMA Premium® motor at bottom) or quickly and easily retrofitted — even in the field — using conductive epoxy. A new Split uKIT simplifies and speeds mounting of the ring on motors with shaft shoulders, slingers, or other end-bell protrusions.

Electro Static Technology

www.est-aegis.com

Filed Under: Bearings, MECHANICAL POWER TRANSMISSION, Motion control • motor controls

Are the fibers in the metal fiber brushes non magnetic. ie Can they be used for current transfer in homopolar motors in the presence of strong magnetic fields ?

AEGIS rings’ microfibers are not magnetic, so they could be used in the presence of strong magnetic fields. I don’t know that anyone has tried using them as contacts in homopolar motors. The fibers are optimized for high frequency ac current rather than dc, but they might work if the current is not too high.

We’re redesigning the bearing arrangement of a 2MW marine propulsion motor which suffers repeated DE bearing failures due to arcing. We’re isolating the DE bearings from the frame (NDE already isolated) and installing an aegis ring or brush for shaft grounding. Is there any benefit in this application of putting the grounding device inboard of the bearings, as opposed to outboard?

Keep the fibers of the shaft grounding ring free of motor bearing grease which will cause the grounding ring fibers to stick together, bend away and lose contact with motor shaft effectively making the shaft grounding ring useless. In a little while you can say goodby to your bearings.

Normally why it was stated that insulated bearing to be fit on NDE side instead of DE side.If only at DE side we use insulated bearing ,what would be the problem….!