(Credit: Phys.org)

A Chinese startups appears to be following in the footsteps of SpaceX as it has lately laid out its own project of reusable space launch system. Link Space, the country’s first private rocket company, has recently presented the design of its New Line 1 (Xin Gan Xian 1) launch vehicle, which could compete with SpaceX’s Falcon 9 in the future.

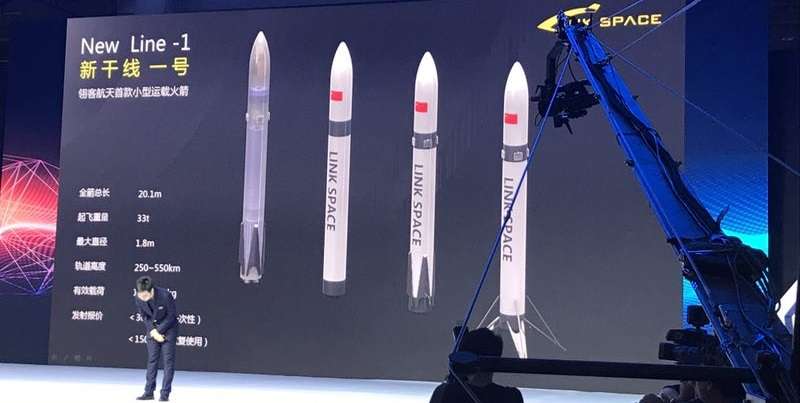

Link Space uncovered the design and some basic technical parameters at a recent presentation. The released images show that the first stage of the newly developed launcher could feature a landing system similar to SpaceX’s flagship reusable Falcon 9 booster.

“SpaceX is very cool, and Falcon 9 is extremely great—we take SpaceX as our goal and guide, because there are many advantages for us to learn,” Hu Zhenyu, founder and CEO of Link Space Aerospace Technology Inc., told Astrowatch.net.

New Line 1 is a Small Launch Vehicle (SLV) designed for microsatellite and nanosatellite launches. It will be capable of sending up to about 440 lbs. (200 kilograms) into a sun-synchronous orbit (SSO) of 155 to 342 miles (250 to 550 kilometers).

New Line 1 will be a 66-foot-tall (20.1-meter), two-stage liquid rocket with a diameter of 5.9 feet (1.8 meters). With a mass of about 33 metric tons at liftoff, the launcher will have a takeoff thrust of about 400 kN. The first stage of the vehicle will consist of four liquid oxygen/kerosene engines with gas generator cycle. Each single booster will have a thrust of 100 kN.

The most important feature of the New Line 1 rocket will obviously be the reusability of its first stage, as with Falcon 9 boosters. This could greatly lower the cost of one single orbital launch.

“The launch price is about 30 million yuan ($4.5 million) for each launch (with a totally new rocket), and this rocket will have an enhanced version with increased takeoff weight. By reusing the first stage of the rocket, the launch price will be reduced to about 15 million yuan ($2.25 million),” Hu revealed.

While the New Line 1 rocket will have only one reusable stage, the company thinks big and aims to develop a second stage that could also be reused after landing. Although it is a long-term goal, Hu hopes that it could be implemented in the successors of the company’s first launch vehicle.

“Perhaps the later version, such as New Line 2 or 3, will have such a capacity,” Hu said.

Founded in 2014, Link Space is a Beijing-based startup with no government or military background. In July 2016, the company achieved rocket hover flight with a single vector-thrust engine for the first time in China. The firm is currently developing key technology for space industry, including a variable thrust liquid rocket engine, a vertical takeoff/vertical landing (VTVL) rocket flight platform, a flight control algorithm and control system, a hover flight test process, a servo actuator and many others.

Through September 2017, Link Space developed three hover rockets, conducted more than 200 flight tests, and accumulated a lot of experimental data and engineering experience. The company uses a rocket flight test field located in Shandong Province covering 53,800 square feet (5,000 square meters)—the biggest commercial rocket test field in China for large-thrust liquid engines and rocket flight tests.

According to Hu, the development of the New Line 1 launch vehicle will consume about 300 million yuan ($45 million) and the maiden flight of the rocket could be conducted as soon as 2020.

“The first orbital flight of New Line 1 is planned in 2020, which is an optimistic estimation, because we know it’s hard, and we plan to develop most of the core technology all by ourselves, such as a deep-variable-thrust liquid rocket engine, flight control system, landing systems and so on,” Hu noted.

Link Space hopes that the New Line 1 rocket will attract the interest of commercial companies worldwide. The company also believes that the launch vehicle will also carry out some missions for the Chinese government.

So far, SpaceX is the only company to recover a rocket following an orbital launch. A few months ago, Elon Musk, founder and CEO of SpaceX, encouraged other companies to develop their own reusable orbital rockets. Now, Link Space’s bold plans show that it could be only a matter of a few years until SpaceX’s monopoly in this field is broken up.

“We also believe that a good technical trend should not belong to a single company, and Elon has said that the reusable rocket is certain to be more and more common. In fact, a lot of similar programs are very different in detail. Although it looks similar in appearance, if you want to make it really work, you must do everything from zero to design and manufacture the whole rocket,” Hu concluded.

Filed Under: Aerospace + defense