As consumer electronic devices become smaller, thinner and more versatile, the space available within these devices for electronic components, such as micro-potentiometers, is also shrinking. The materials chosen for these applications must exhibit a balance of characteristics. These include self-extinguishing behavior upon exposure to flame, dimensional stability, creep resistance at high temperatures, sufficient mechanical and electrical performance, ease of coloring, ease of processing for thin wall parts in multi-cavity tools, and ability to withstand Surface Mount Technology (SMT) temperatures and solder materials.

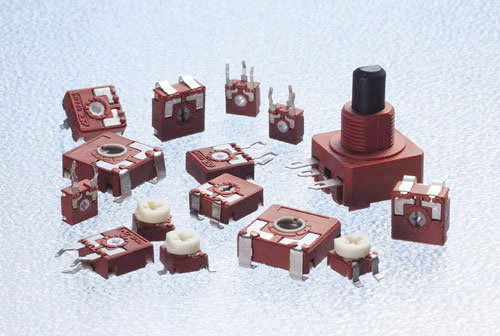

PolyOne engineered materials experts worked closely with ACP, a leading manufacturer of electronics components, to develop a non-halogenated flame retardant material able to be used in existing injection molds. ACP (Aragonesa de Componentes Pasivos SA; Tarazona, Spain) micro-potentiometers are critical for dividing voltage and measuring electric potential to control volume and other levels in industrial and consumer electronic devices. The material ACP selected was Edgetek™ AM Non-Halogenated Flame Retardant Solutions. This material is cost-efficient and environmentally suitable for molding these micro-potentiometers.

This, in turn, helped ACP differentiate its offerings from those of its competitors and achieve its sustainability goals. PolyOne’s close collaboration with ACP also enabled a fine-tuning of the Edgetek™ AM for optimal performance and processing.

PolyOne Corp.

www.polyone.com

Filed Under: Semiconductor manufacture, ELECTRONICS • ELECTRICAL

Tell Us What You Think!