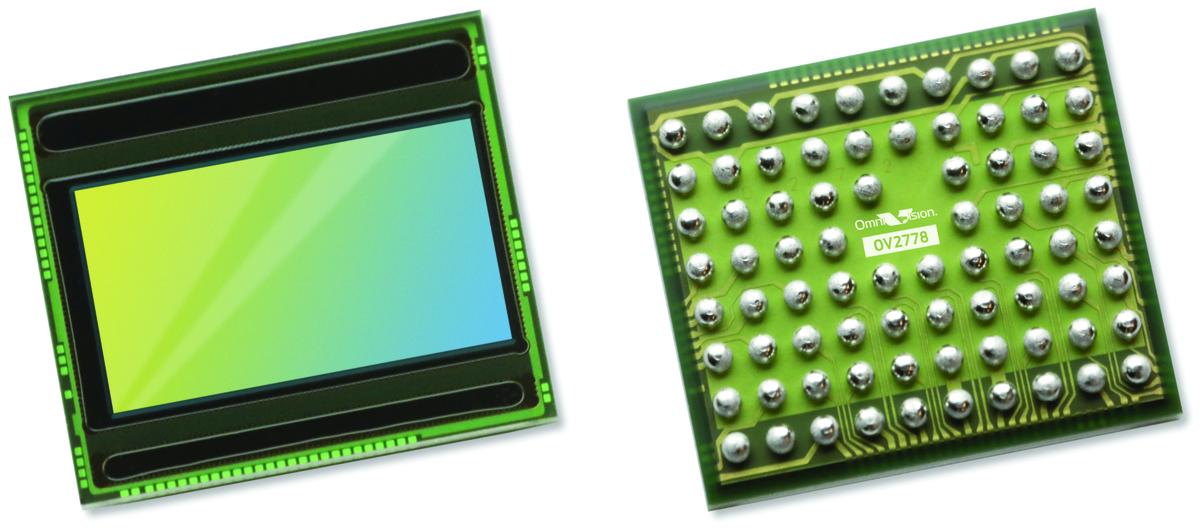

OmniVision Technologies, Inc., a leading developer of advanced digital imaging solutions, today announced the OV2778 automotive image sensor, which provides the best value of any 2MP RGB-IR sensor for cabin- and occupant-monitoring. With its complement of industry-leading features, this sensor is ideal for interior applications such as detecting packages and unattended children, as well as videoconferencing. The OV2778 comes in the smallest package available for the automotive in-cabin market segment—a 6.5 x 5.7mm automotive CSP—enabling the smallest camera sizes possible for unobtrusive placement inside the vehicle. It also offers advanced ASIL functional safety, which is important for in-cabin applications when the OV2778 is being integrated as part of an ADAS system.

“Demand for cabin and occupant monitoring are accelerating growth in the global automotive image sensor market,” said Thilo Rausch, product marketing manager at OmniVision. “Our new OV2778 image sensor enables these applications in mainstream vehicles by providing the best value with high sensitivity across all lighting conditions.”

The OV2778 is built on OmniVision’s 2.8-micron OmniBSI™-2 Deep Well™ pixel technology, which delivers a 16-bit linear output from a single exposure with best-in-class low-light sensitivity. With the second exposure, the dynamic range increases to 120dB, which minimizes motion artifacts. With leading low-light performance, this sensor is ideally suited for in-cabin applications. Additionally, with an integrated RGB-IR, 4×4 pattern color filter and external frame synchronization capability, the OV2778 yields top performance across varying lighting conditions.

This image sensor is AEC-Q100 Grade 2 certified for automotive applications. It also benefits from the large installed base of its predecessor, enabling the OV2778 to be easily integrated into existing automotive platforms.

OV2778 samples are available now, along with a plug-and-play automotive reference design system that can be connected to any vehicle for rapid development. This image sensor will be demonstrated at the Auto Shanghai trade show, April 18-20, by appointment only. Contact your OmniVision sales representative to schedule a meeting or for more information: www.ovt.com/contact-sales.

Filed Under: Aerospace + defense, Product design