Motion-component suppliers surveyed for this year’s Design World Trends issue described several different programs to maintain technical proficiency for both application engineers and OEMs and other users of their products. CGI Motion engages in outreach in the form of open houses so that STEM students get chances to tour the company facility. That’s from Robert […]

Control-software portability with IEC 61131-3: How reusable are XML files?

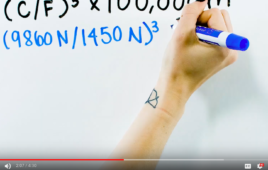

Say an engineering team wants to switch their design’s PLC from one model to another — a relatively infrequent but ordinary specification decision. How well do XML files really work for importing and exporting? How much are component manufacturers really motivated to make that work … and not lock engineers onto one specific hardware? Engineers […]

Programmable automation controllers (PACs) work as an alternative to what exactly?

According to some, today’s most demanding motion designs either incorporate a PAC or industrial PC — and these are engineers’ two leading options for machine control right now. Recall that until recently, industrial automation (including motion control) was extremely segmented. So supervisory control and data acquisition (SCADA) systems were at the system top layer … […]

IEC 61131-3 programming: Where’s structured text more appropriate than ladder logic?

No one IEC 61131-3 language leads for all uses. In fact, the best way to program with IEC 61131-3 languages is by using multiple languages together. That accommodates (among other things) the way every engineer has a different methodology for programming. Sequential function chart (SFC): Recall that SFC is the highest-level code standard in IEC […]

Not just Allen Bradley anymore: New controllers abound

10 years ago, there was one main controller brand in U.S. automation — Rockwell Automation’s Allen Bradley. This is still a leading PLC line with a massive adoption rate in the U.S. because: • Allen Bradley did an excellent job educating people in the U.S. on ladder-diagram programming for its PLCs • The manufacturer embedded […]

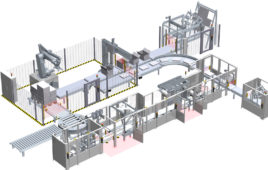

Parker Hannifin Corp. now offers free software — Parker T-Slot Aluminum Design Architect

Parker’s Electromechanical and Drives Division North America now offers Parker T-Slot Aluminum Design Architect, which lets users of any skill level quickly and easily design products from Parker T-slot aluminum framing components. The software takes the challenging task of designing products from T-slot aluminum and makes it as simple as building with snap-together blocks. Available…

Parker Hannifin high-precision electromechanical solutions at Photonics West 2019

Parker’s Electromechanical and Drives Division will be exhibiting at SPIE Photonics West 2019 in San Francisco, February 5 to 7, 2019. Every year, more than 20,000 attendees come to the world’s largest photonics technologies event to learn about the latest research as well as find the latest devices and systems that use new technologies to […]

Choosing the right stage actuation for dynamic-metrology applications

When measurements are made to discrete product on the fly, it’s key that the motion system minimize error and correct for the rest. Brian Handerhan | Business development manager • Life sciences Patrick Lehr | Product manager • Precision mechanics Electromechanical & Drives Division • Parker Hannifin Corp. Dynamic metrology is the collection of data […]

New Parker Hannifin ACRView Motion Development Software with full Windows 10 support

Parker’s Electromechanical and Drives Division North America has released ACRView version 6.4.2, which lets users develop applications using the Windows 10 operating system from Microsoft. ACRView is a powerful code-development tool that assists users of ACR controller and IPA drive products to program, debug, and commission their application. Several features are incorporated to assist both […]

Webinar: Integrating Hydraulics and Electrical Drive Technologies

Discussion of a new technology for hydraulic systems in modern industry. The integration of hydraulics with electrical drive technologies can help reduce energy costs while providing more efficient and quieter machinery. Join us on June 6th to understand the basic principle, review a case study of the application and discuss the implications in…

How does extreme heat affect hydraulic hose?

In a previous posting, the editors at Fluid Power World discussed how ultra-low temperatures can play havoc with the performance of typical rubber hose. Hydraulic hose used at high temperatures faces performance issues too, but for different reasons. That’s because thermal exposure can cause aging of elastomers and plastics. (Other causes of aging include exposure […]

The post How does extreme heat affect hydraulic hose? appeared first on Hose Assembly Tips.

Aerospace regulations can prove challenging for successful design projects

Edited by: Paul J. Heney, Editorial Director There’s a rough rule of thumb that’s widely observed in aircraft system design and development: It usually takes at least five years to go from the original concept of a new system to the point at which the FAA issues a Type Certificate, so that an actual aircraft…

Parker expands mobile-controls offerings

The Electronic Controls Div. of Parker Hannifin recently introduced several additions to its IQAN portfolio of hardware and software products, intended to improve performance and simplify the control…

Reader question: Now THIS is a mobile filter!

By Josh Cosford We get regular reader letters, sometimes giving feedback or opinions on articles, but most often asking questions about a topic. One such reader is Ed…

![]()

Sensors eliminate information gaps

The SensoNODE Blue and SCOUT Mobile help eliminate massive information gaps by catching and reporting performance fluctuations that could damage assets over time. By monitoring assets and tracking data, users can employ predictive maintenance routines to address even the smallest issue before it snowballs into a serious problem. The wireless SensoNODE sensors are for portable…

New plating keeps fittings rust-free for up to 1,000 hours

Parker Hannifin has now enhanced their tube fittings and adapters with ToughShield (TS1000) plating, which keeps fitting rust free up to 1,000 hours, according to ASTM B117 neutral…

The post New plating keeps fittings rust-free for up to 1,000 hours appeared first on Hose Assembly Tips.

Parker development in plating hydraulic tube fittings and adapters for longer corrosion resistance

Parker Hannifin Corporation, a developer of motion and control technologies, has enhanced their tube fittings and adapters with ToughShield (TS1000) plating, which keeps fitting rust free up to 1,000 hours, according to ASTM B117 neutral salt spray tests. The superior coating is the result of years of investment in metallurgical and surface analysis capabilities. “The

Windpower Engineering & Development

![]()

Parker announces North American production of high moment rodless linear actuator series

Now manufactured in the USA, the HMR attains greatly improved lead times and new customization options. Parker’s Electromechanical Automation Division, a leading supplier of motion control technology, is pleased…

![]()

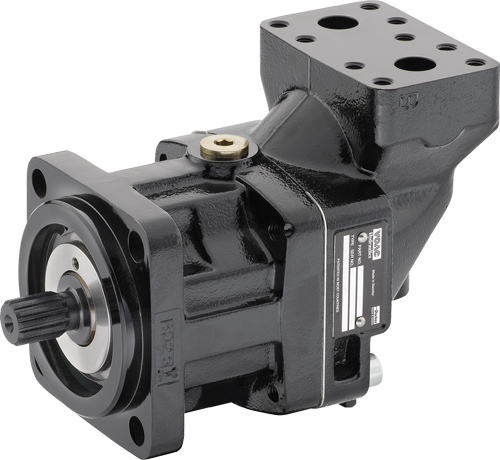

Select the right motor for your hydraulic applications

By Justin Wheeler, CFPHS, C-Series/Bent Axis Project Manager, Hydraulic Pump Div., Parker Hannifin The ideal in hydraulic system design is to match overall efficiencies to the application performance expectation. This requires the…

![]()

What motor manufacturers must do for robot makers and users

By Jeff Nazzaro Gearhead and Motor Product Manager Parker Hannifin Corp. Electromechanical Automation, NA Robotics represents different things to different industries. When it comes to propulsion, arm joint manipulation, turret rotation, and so on, many robotic manufacturers benefit from using frameless versus housed motors. The benefit comes from the options made possible by incorporating motors…

12 questions to answer for shredding equipment design

By Dave Ebert, Product Manager, Gold Cup Pumps & Motors, Hydraulic Pump Div., Parker Hannifin Corp. High-production shredding applications reduce material—appliances, concrete, tires, and so on—into smaller particles…

Intelligent amplifier works as a servo-drive/controller

Parker’s Electromechanical Automation Division now sells Intelligent Parker Amplifiers or IPAs—1.5-axis servo-drive/controller combinations based on the ACR control platform. Available in two power levels—400W and 1,500W—the IPA can drive…

New ETH125 high-force electric cylinder from Parker

Parker’s Electromechanical Automation Division has released the ETH125 electric cylinder, a 125 mm frame size actuator. Parker’s latest addition to the ETH product line serves to further extend…

Parker Expands XE Line of Linear Actuators

Parker’s Electromechanical Automation Division has expanded its XE line of linear actuators to include the 401 XE. The new 401 XE is now the smallest ball screw driven…

Parker Uses Electroactive Polymer Technology

Parker Hannifin Corporation, the provider of motion and control technologies, today announced that it is embarking on the development of new smart sensors and actuators using electroactive polymer…