Daytime running lights have become mandatory by EU Standards as of recently and are a popular style element. Their complex 3-D shape represents a challenge for joining technology. The ultrasonic welding tool can be easily adapted to the design type by means of studs in various heights. Short cycle times and indexed tool change kits allow for time-saving application and for an ever increasing variety of variants. Ultrasonic specialist Herrmann Ultrasonics has just delivered a big order to an automotive supplier. The order included two machines with fifteen spare sets.

Ultrasonic welding for joining of thermoplastic materials is a widely established joining method in the automotive industry. Applications range from interior (side door trims, center console) to engine compartment (cylinder head cover, engine covers) through to lighting, such as tail-lamp units of daytime running lights.

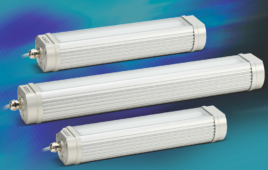

Daytime running light with complex joining geometry

Ultrasonics allows for gentle component handling

The conventional joining technologies reach their limits with asymmetrical components. One limit may be uneven temperature distribution during i.e. mirror-imaged welding. Some points may become too hot and produce threads; other points may remain cold and are not able to bond homogeneously. With vibration welding additional space is required so that the joining zone becomes significantly larger. A large amount of molten material is produced, which may be projected out of the welding spot. Ultrasonic tools vibrate with a frequency of 20.000 Hz or more. In case of complex, asymmetrical parts, ultrasonics may be subject to physical limits. However, if the weld tool, i.e. the Sonotrode, is correctly dimensioned and applies the vibrations correctly, ultrasonics represents a number of advantages:

- Sensitive component surfaces are treated gently

- Targeted energy input protects reflectors and LEDs

- 3-D shapes are realized more easily

- Short weld cycles between 100 and 300 milliseconds

- Smaller machine footprint compared to other joining processes

Composite sonotrodes with screw-in studs adapts to the 3-D shapes

Stud Sonotrodes for 3-D components

For 3-D shapes such as the daytime running light, the ultrasonic Sonotrode is separated in two elements: a Composite Sonotrode with individually fixed single Sonotrodes, referred to as screw-in studs; every individual stud represents a small vibrating Sonotrode. In order to guarantee correct vibration, the Composite Sonotrode is calculated by means of the Finite-Element-Method (FEM) and gauged for frequency, idling power and amplitude. Every individual stud must also be gauged for frequency. This is where the know-how of the ultrasonics specialist Herrmann Ultrasonics comes in, for the studs are designed in various lengths and for different interfering contours, i.e. for leaving a cutout for lettering on a component. This has an influence on the vibrating behavior.

Laser gauging of the screw-in studs

In order for the single Sonotrodes (studs) to vibrate correctly, they are individually mounted and adjusted in a difficult manual process.

Under load simulation, the completed Sonotrode is laser-gauged and the required corrections are performed by machining processes. Software which was specifically developed for this purpose, measures up to 100 measuring points to create the amplitude profile. If necessary, tension corrections will be made. However, the right frequency, no load power and amplitude have to be reached.

For all ultrasonic processes it is important that the Sonotrode, the fixture and the component to be welded form a unit and are not separated during the tool replacement process. All parts are installed in a complete replacement frame and form a firmly setup “tool cube” which can be exchanged and stored problem-free, if a different part needs to be welded.

Herrmann Ultrasonics

www.herrmannultrasonics.com

Filed Under: Lights • signal lamps • indicators

Tell Us What You Think!