The OPAK research project, subsidized in Germany by the Federal Ministry of Economics and Energy, brings together public and private organizations to develop Industry 4.0 enabling technologies.

The term Industry 4.0 refers to the idea that manufacturing is undergoing a fourth industrial revolution characterized by the individualization of products under the conditions of highly flexible production. Tasks that are currently still performed by a central master computer will be taken over by components. Components will network with one another in an intelligent way, carry out their own configuration with minimal effort, and independently meet the varying requirements of production.

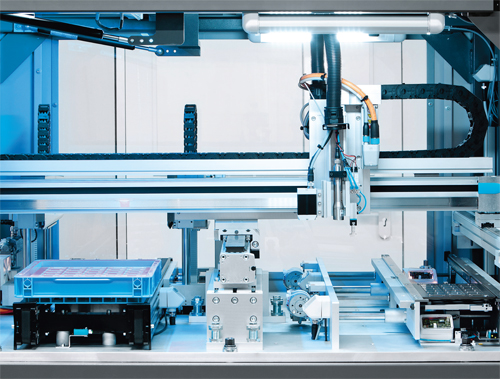

The first outcome of the research activities in the OPAK project is a prototype of an integrated stopper module: the CPS-Gate.

Prototypes like the CPS-Gate are proof of the kinds of flexible plug-and-play components that will be vital to implementing Industry 4.0. The CPS-Gate prototype incorporates, in one component, all the functionality required for stopping work piece carriers on a conveyor belt—functionality that currently resides in individual components and systems, including PLCs, sensors, actuators, RFID/NFC technology and communication functions within an MES/ERP application. The CPS-Gate prototype will be incorporated within Festo Didactic Learning Systems facilities for training on Industry 4.0 concepts.

Festo and Siemens have collaborated on an Industry 4.0 product, the Multi-Carrier System. This machine transport system enables high flexibility in work piece transfer. The system moves work pieces freely and synchronously to the process at hand and can be integrated within the existing material flow—including seamless loading and unloading of carriages. The system also allows for quick conversion of the machine to various formats to accommodate a range of product types. It supports overall integration of transport movements, motion control functionality and coordination of additional machine modules.

Industry 4.0 will create an environment where plant engineering will be carried out faster, more intuitively and more efficiently than presently possible. Under Industry 4.0, individual automation components will be more intelligent and production facilities will be more flexible.

To make the engineering process more intuitive and efficient, a virtual emulation of the production plant is generated within an OPAK framework. This allows all processes and functions within the plant to be simulated and tested by means of engineering software before a plant is built.

As a requirement for generating a virtual emulation of a production plant, the automation components must incorporate all the information needed for operation within an integrated and networked controller environment. These components must have adaptable interfaces that minimize assembly time and create as close as possible plug-and-play operation. The work that is being carried out by Festo and other OPAK program partners is focused on small-scale systems that will be transferable to the factory of the future. The CPS-Gate embodies all these principles.

Festo

www.festo.com/usa

Filed Under: Uncategorized

Tell Us What You Think!