In the aerospace, automotive, semiconductor, and medical sectors, it is vital that fastener through-holes are chamfered and free of metal burrs caused by the hole cutting process to ensure a flawless fit and durability when parts are assembled. However, some manufacturers continue to experience costly and time-consuming hand benching operations where components are taken offline from the CNC operations so that chamfered holes can be deburred and finished by hand.

In combination with the Heule cutting tools, the Flex-Hone is used for final deburring of through-holes, which is often an expensive and time consuming hand (bench) operation.

For this reason, increasingly more companies are automating this process by incorporating a combination of cutting, edge breaking, and deburring tools with a flexible hone called the Flex-Hone to provide a smooth finish without hand benchwork. According to Gary Brown, vice-president and general manager of Heule Tool of North America, “Any time you drill a hole into nickel, Inconel, waspalloy (nickel-cobalt alloy), titanium, or stainless steel, you create a burr. A precise, smooth through-hole is often a crucial requirement. In many applications, there are several components, either static or rotating parts that are assembled together. It is critical that the hole drilling and edge breaking processes be performed so that the parts stay together, which is particularly important with the rotating parts.”

He also said that to avoid delays and keep costs low, some shops are automating this process and incorporating Heule’s precision chamfering tool and universal deburring tools with a ball-style hone called the Flex-Hone from Brush Research Manufacturing (BRM) that provides the final step in providing flawless finish.

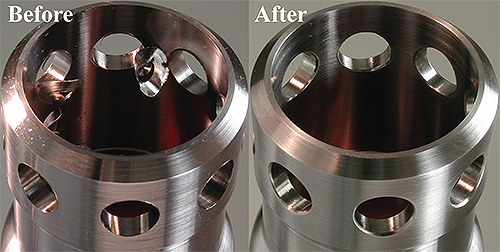

Here’s an example of a through-hole before and after undergoing the deburring process with a Flex-Hone tool from Brush Research Manufacturing. For some parts, the hole drilling and edge breaking processes must be performed together rather than disassemble the parts.

The chamfering tool, available in sizes from 0.157 in. to 1.750 in., is a double-bladed chamfering tools that creates pre-adjusted front and back chamfers in a single pass without stopping or reversing the spindle. Using this tool, exact chamfer diameters can be set without trial and error.

The deburring tool blade, available in sizes from 0.157 in. to 1.614 in., cuts a smooth tapered edge break from 0.005 to 0.020 in., based on the tool size. A cassette option is available for larger holes. The patented design incorporates a Tin- or TiAlN-coated carbide blade that allows for faster feeds and speeds, and provides a long tool life.

The Flex-Hone from Brush Research is characterized by the small, abrasive globules that are permanently mounted to flexible filaments. A flexible, relatively low-cost tool, it is utilized for ultra-fine surface finishing, de-burring, plateau finishing and edge-blending.

The Flex-Hone, available in standard sizes beginning at 4 mm (custom sizes and abrasives are available) is characterized by the small, abrasive globules that are permanently mounted to flexible filaments. A flexible, relatively low-cost tool, it is utilized in the manufacturing marketplace for ultra-fine surface finishing, de-burring, plateau finishing and edge-blending.

“Our tool cuts through the metal and puts the beveled edges on the front and back of the metal part,” explained Brown. “It also removes the drill burrs and drill caps that are created by the drill or reamer or end mill. Our tools also perform the edge-breaking step. But we also recommend the Flex-Hone to go in after we have created these beveled edges, and the flexible hone will round the transition between the beveled edge and the hole.”

Discuss this on the Engineering Exchange:

Brush Research Mfg., Inc.

www.brushresearch.com

Heule Tool of North America

www.heuletool.com

Filed Under: Aerospace + defense, Software • CAM, Automotive, Semiconductor manufacture, Medical-device manufacture

Can the Flex-Hone be used with composites material without fraying or delamination in stacks of composites and other metallic stacks of material in aircraft assembly.