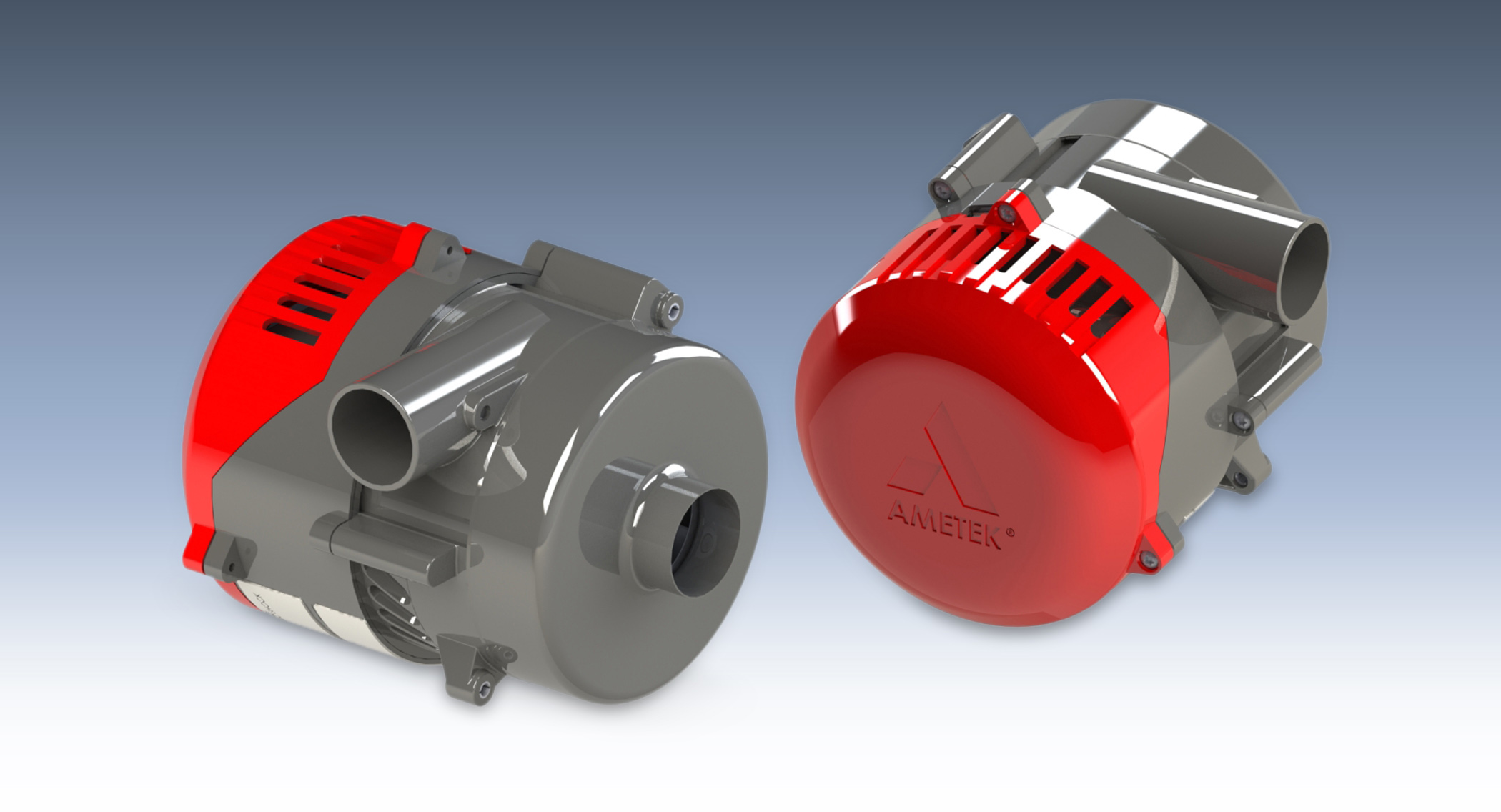

New Windjammer PRO Series blowers from AMETEK Dynamic Fluid Solutions (DFS) are powerful blowers with new design and performance enhancements for high-flow applications.

Windjammer PRO Series enhancements include the ability to run multiple performance profiles depending on application requirements: Universal Voltage Common Performance (UVCP) lets the blowers deliver the same performance whether on 120 Vac or 240 Vac input. That feature is especially important for OEM products designed for global markets.

Windjammer PRO brushless blowers offer greater performance and efficiency than traditional designs.

The new Windjammer PRO Series blowers get greater efficiency and greater airflow than competitive models. The blowers feature a cooling chamber that provides for a lower operating temperature, extending blower life. They also incorporate proprietary technology that reduces noise output, as a redesigned motor enclosure and improved air and noise channeling make the Windjammer PRO Series one of the quietest high-flow designs available.

Windjammer brushless bypass blowers are virtually maintenance free and suitable for a wide array of air-moving applications, including fume evacuation and material handling. Along with improved motor cooling, the PRO Series features shaft and bearing assembly redesigns that extend the life of bearings and sensitive electronic modules. Improved sealing prevents contaminants from reaching the bearings, and more extending their life as well.

Next-generation controller software adds improved flexibility to the Windjammer PRO’s features. Custom speed and acceleration profiles, overcurrent safety limits, and error logging are some of the software functions.

Along with Windjammer brushless blowers, AMETEK DFS offers Nautilair brushless blowers, ROTRON regenerative blowers, DurA-Tek Prime pumps and MICROjammer variable-speed brushless blowers; transportation blowers, motors, pumps and fans. For more information, visit www.ametekdfs.com.

You may also like:

Filed Under: Blowers, Material handling • converting, MOTION CONTROL, MORE INDUSTRIES