Vesconite Bearings recently produced both the smallest and largest vanes in its history. This achievement underscores Vesconite Bearings’ commitment to engineering vanes in air motors, vacuum pumps and concrete vibrators to maximize efficiency, reliability and performance.

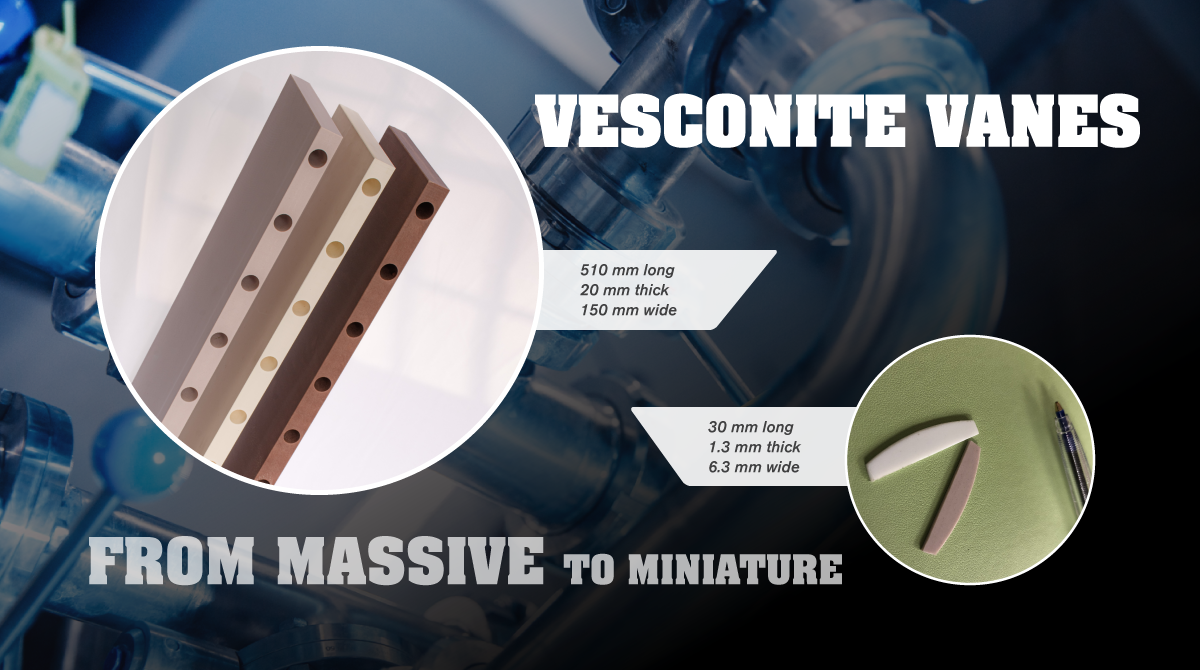

In June, Vesconite Bearings successfully crafted the tiniest vanes to date, measuring a mere 1.3 mm in thickness, 6.3 mm in width, and 30 mm in length. These precision-engineered vanes were specifically produced for testing by an air motor manufacturer based in Italy. Each air motor incorporates five of these vanes, showcasing the precision and craftsmanship for which Vesconite Bearings is known.

The small vanes are made from Vesconite Hilube and Vesconite Superlube wear materials, both of which boast low coefficients of friction. Particularly noteworthy, Vesconite Superlube stands out as an ultra-low-friction wear material with friction levels even lower than virgin polytetrafluoroethylene (PTFE). Testing is underway to determine the optimal wear material for this application.

Meanwhile, Vesconite Bearings has also achieved production success in the opposite direction, producing what are possibly the largest vanes it has produced to date. Measuring an impressive 510 mm in length, 20 mm in thickness, and 150 mm in width, pairs of these sizable vanes are destined for trial in vacuum pumps by a South African vacuum pump repairer and supplier. Crafted from Vesconite Superlube, Hitemp 160, and Hitemp 150 wear materials, these vanes offer different characteristics, including an ultra-low coefficient of friction in the case of Vesconite Superlube, incredible chemical resistance in the case of Hitemp 160; and excellent abrasion-resistant properties in the case of Hitemp 150.

The coming months will see comprehensive testing of each material — Vesconite Superlube in September, Hitemp 160 in October, and Hitemp 150 in November — to determine the most suitable wear material for this application.

Vesconite Bearings senior sales consultant Phillip de Villiers and Vesconite Bearings engineer Jandri Ueckermann describe how the manufacturing process for these vanes showcases Vesconite Bearings’ dedication to precision engineering. For the small 1.3 mm thick vanes, the manufacturing procedure involved the challenges of machining thin plates to the target thickness, and then profiling to shape.

“We’re excited to have these large and small reference case studies that demonstrate the vane production capabilities,” says Vesconite Bearings senior sales consultant Phillip de Villiers.

“Our ability to manufacture both the smallest and largest vanes, along with the expertise in developing wear materials for distinct operational conditions, reflects the commitment to providing tailored solutions for the clients,” he notes.

“Vesconite Bearings continues to push the boundaries of engineering and innovation, reaffirming its position as an industry leader in bearing and wear solutions,” adds Ueckermann. “With a proud history of addressing diverse needs and a forward-looking approach, the company remains at the forefront of delivering cutting-edge solutions to a global clientele,” she says. For more information, visit vesconite.com.

You may also like:

Filed Under: MANUFACTURING, MORE INDUSTRIES